Plasma cutters use ionized gas to cut conductive metals. Choosing the right cutter depends on material thickness, duty cycle, air supply, and cut quality requirements—not just amperage rating.

Key Specifications Explained

Amperage Rating & Cut Capacity

| Amperage | Recommended Cut | Maximum Cut | Typical Material |

|---|---|---|---|

| 20-30A | 1/8”-3/16” | 1/4” | Sheet metal, auto body, HVAC |

| 40-50A | 1/4”-3/8” | 1/2” | Light fabrication, farm repair |

| 60-80A | 3/8”-1/2” | 3/4” | General fabrication, structural steel |

| 85-100A | 1/2”-3/4” | 1” | Heavy fabrication, thick plate |

Recommended cut = Clean cut with minimal dross (slag on bottom edge)

Maximum cut = Severance cut (rough edge, heavy cleanup required)

Rule of thumb: Buy 20-30% more amperage than your typical material thickness for clean cuts and longer consumable life.

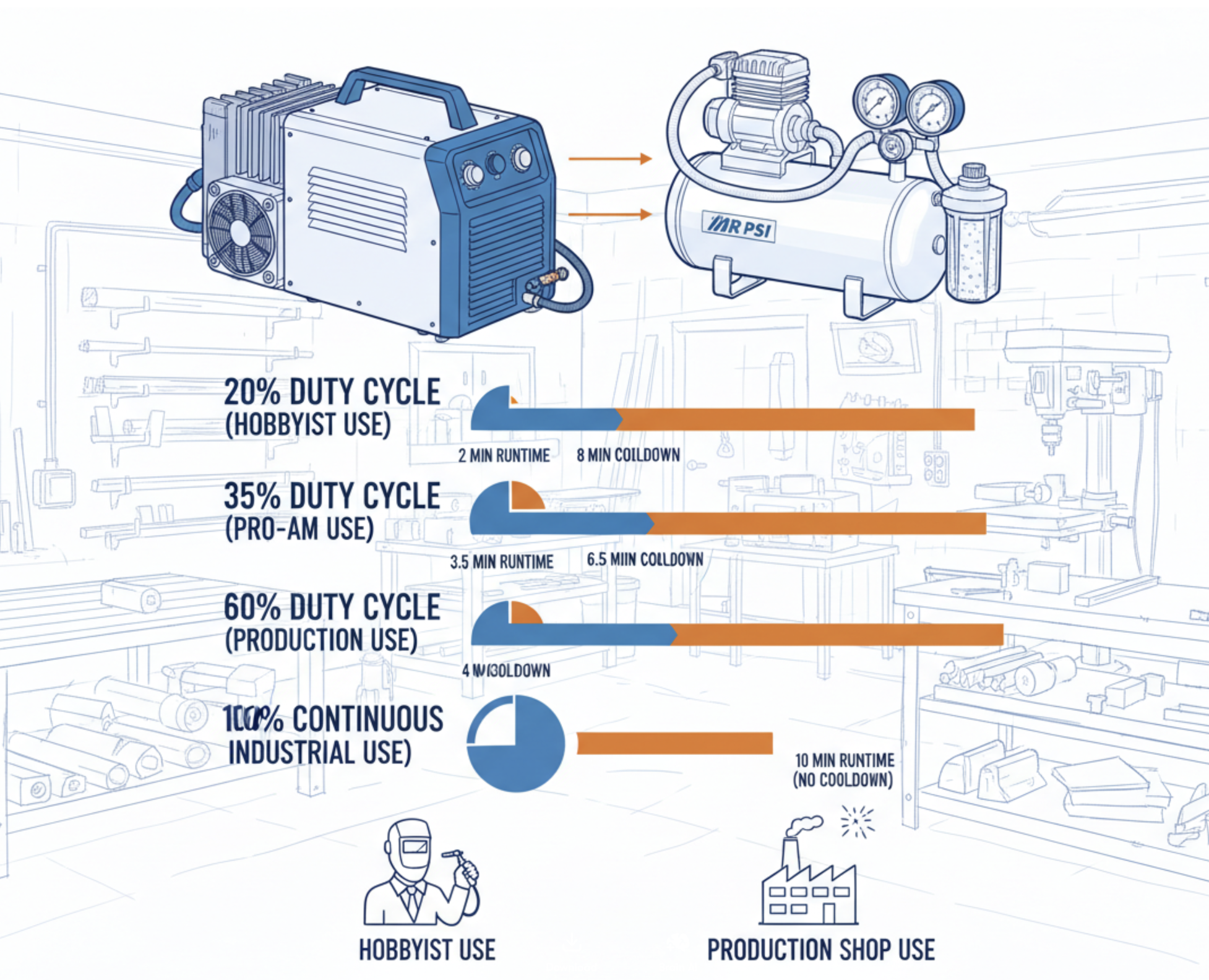

Duty Cycle

Definition: Percentage of 10-minute period the machine can run at rated amperage before requiring cooldown.

| Duty Cycle | Runtime @ Max Amps | Cooldown | Use Case |

|---|---|---|---|

| 20% | 2 min | 8 min | Hobbyist, occasional use |

| 35% | 3.5 min | 6.5 min | Light fabrication, DIY |

| 60% | 6 min | 4 min | Production shop, frequent use |

| 100% | 10 min | 0 min | Industrial, continuous operation |

Example: 50A cutter with 35% duty cycle can run 3.5 minutes at 50A, then must cool 6.5 minutes.

At lower amperage: Duty cycle increases (50A cutter at 30A may have 60-80% duty cycle).

Air Supply Requirements

Compressed Air Specs: – Pressure: 60-90 PSI (4-6 bar) – Flow rate: 4-8 CFM @ 90 PSI (varies by amperage) – Quality: Clean, dry, oil-free

Compressor Sizing:

| Plasma Amperage | Minimum CFM @ 90 PSI | Recommended Tank Size |

|---|---|---|

| 20-30A | 4 CFM | 20 gallon |

| 40-50A | 5 CFM | 30 gallon |

| 60-80A | 6 CFM | 60 gallon |

| 85-100A | 8 CFM | 80 gallon |

Air quality issues: – Moisture = premature consumable failure and poor cut quality – Oil contamination = torch tip clogging – Solution: Install inline air dryer/filter between compressor and plasma cutter

Input Power Requirements

120V Plasma Cutters: – Amperage range: 12-40A – Cut capacity: Up to 3/8” recommended, 1/2” maximum – Advantage: Portable, runs on standard outlets – Limitation: Lower duty cycle, reduced cut speed

240V Plasma Cutters: – Amperage range: 40-100A+ – Cut capacity: 1/2”-1”+ recommended – Advantage: Higher duty cycle, faster cutting, thicker material – Requirement: Dedicated 240V circuit (30-50A breaker)

Dual Voltage (120V/240V): – Runs on both voltages with reduced performance on 120V – Example: 50A on 240V, 30A on 120V – Best for: Portable use + shop capability

Cut Quality Factors

Pilot Arc vs. Contact Start

Pilot Arc (High-Frequency Start): – Arc initiates without touching workpiece – Pros: Cuts expanded metal, grating, rusty/painted steel – Cons: Higher cost, can interfere with electronics – Best for: Versatile cutting, field work

Contact Start (Scratch Start): – Requires torch tip contact with workpiece to start arc – Pros: Lower cost, no electronic interference – Cons: Cannot cut expanded metal or start on edge – Best for: Budget cutters, clean flat plate

Inverter vs. Transformer Technology

Inverter-Based: – Weight: 10-40 lbs (portable) – Efficiency: High (lower power consumption) – Duty cycle: Typically higher (35-60%) – Cost: Moderate to high – Best for: Modern shops, portability required

Transformer-Based: – Weight: 80-200 lbs (stationary) – Efficiency: Lower (higher power draw) – Duty cycle: Often 100% (industrial use) – Cost: Higher upfront, lower long-term maintenance – Best for: Heavy industrial, continuous operation

Consumable Costs & Life

Consumable Components

| Part | Function | Typical Life | Cost per Set |

|---|---|---|---|

| Electrode | Conducts current to arc | 1-3 hours cutting time | $3-$8 |

| Nozzle (tip) | Focuses plasma stream | 1-3 hours cutting time | $2-$5 |

| Swirl ring | Stabilizes gas flow | 5-10 hours | $1-$3 |

| Shield cup | Protects nozzle | 10-20 hours | $2-$5 |

Consumable life factors: – Amperage setting (higher amps = shorter life) – Air quality (moisture/oil reduces life 50%+) – Arc-on time (duty cycle) – Proper technique (perpendicular torch angle, correct standoff)

Annual consumable cost estimate: – Hobbyist (20 hours/year): $50-$100 – Light fabrication (100 hours/year): $250-$500 – Production shop (500+ hours/year): $1,500-$3,000

Material Compatibility

| Material | Plasma Cut | Notes |

|---|---|---|

| Mild steel | ✓ | Best cut quality, minimal dross |

| Stainless steel | ✓ | Clean cuts, some dross on thick sections |

| Aluminum | ✓ | Requires higher amperage than steel (30% thicker capacity) |

| Copper | ✓ | High thermal conductivity = slower cut speed |

| Brass | ✓ | Similar to copper, produces toxic fumes (ventilation required) |

| Cast iron | ✓ | Brittle, may crack from rapid heating |

| Galvanized steel | ✓ | Toxic zinc fumes (ventilation mandatory) |

Cannot cut: Non-conductive materials (wood, plastic, concrete, glass)

Torch Styles & Ergonomics

Hand Torch (Standard)

- Cable length: 10-25 feet

- Weight: 1-3 lbs

- Best for: Freehand cutting, portability

- Limitation: Less precise than machine torch

Machine Torch (CNC-Compatible)

- Mounting: Designed for CNC table or track system

- Standoff: Adjustable height control for consistent cut quality

- Best for: Automated cutting, production runs

- Cost: $200-$800 (in addition to hand torch)

Ergonomic Features

- Trigger lock: Reduces hand fatigue during long cuts

- Swivel head: Prevents cable twist, improves maneuverability

- Insulated grip: Protects from heat during extended use

Common Mistakes

Undersizing amperage for material thickness

40A cutter on 1/2” steel = slow, rough cuts and rapid consumable wear. Size cutter 20-30% above typical thickness for clean cuts.

Using contaminated air supply

Moisture and oil in compressed air destroy consumables in 10-20% of normal life. Always use inline air dryer/filter.

Running at maximum amperage continuously

Exceeds duty cycle, triggers thermal shutdown. Run at 70-80% of rated amperage for longer duty cycle and consumable life.

Buying Checklist

- ✓ Amperage rating 20-30% above typical material thickness

- ✓ Duty cycle matches usage frequency (35%+ for regular use)

- ✓ Input voltage compatible with available power (120V or 240V)

- ✓ Pilot arc start for versatile cutting (expanded metal, rusty steel)

- ✓ Inverter technology for portability and efficiency

- ✓ Compressor meets CFM and PSI requirements

- ✓ Air dryer/filter included or purchased separately

- ✓ Consumable availability and cost verified

Leave a Reply