Weld symbols are the universal language of welding blueprints, and if you’re in the welding trade or fabricating anything structural, knowing how to read them is essential. Whether you’re welding on a shop floor, out in the field, or designing something in CAD, understanding these symbols can save time, eliminate guesswork, and prevent costly mistakes.

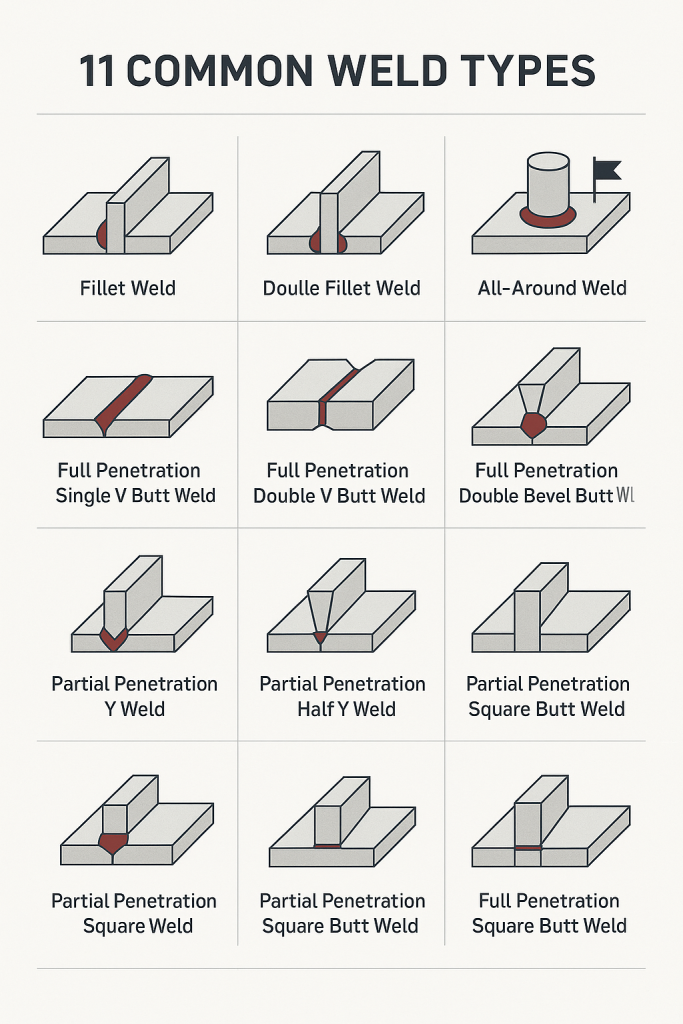

In this guide, we break down the most common weld types and symbols, as illustrated in the image above. We’ll keep it simple and practical so you can identify the weld type, understand its application, and recognize the symbol used on technical drawings.

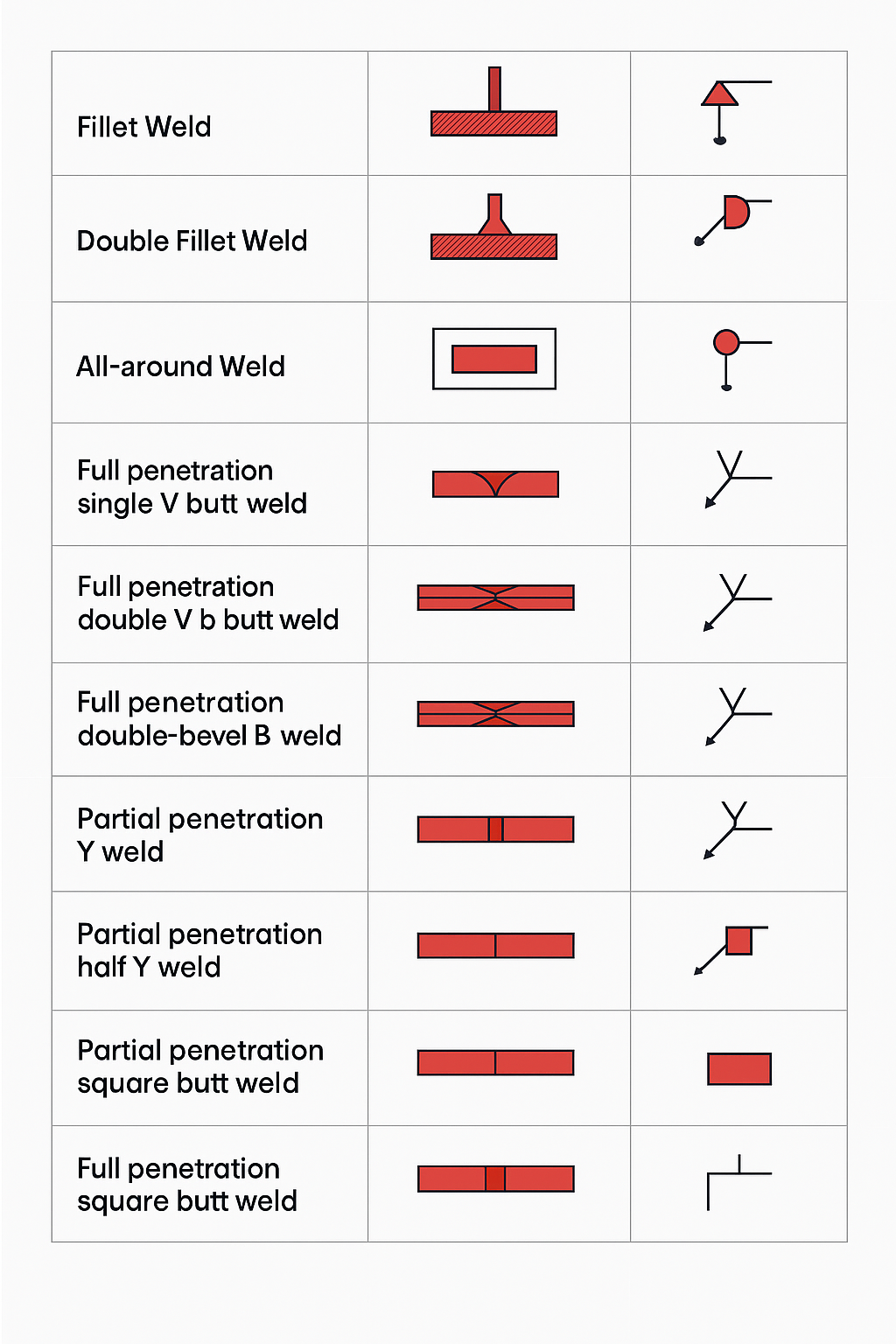

1. Fillet Weld

- Visual: Triangular weld filling the corner of two perpendicular pieces.

- Symbol: A simple triangle on the reference line.

- Use: Common in T-joints, lap joints, and corner joints. Found everywhere from structural steel to trailers.

2. Double Fillet Weld

- Visual: Fillet welds on both sides of a joint.

- Symbol: Two triangles, one on each side of the reference line.

- Use: Used when strength is needed from both sides — think brackets, frames, and reinforced joints.

3. All-Around Weld

- Visual: Fillet or groove that wraps completely around a joint.

- Symbol: A small circle at the junction of the arrow and reference line.

- Use: Critical for pipe joints or tube frames that require full reinforcement around the entire circumference.

4. Site Weld

- Visual: Indicates that the weld is to be done on-site, not in a shop.

- Symbol: A small flag at the intersection of the arrow and reference line.

- Use: Helpful for projects where transport, fit-up, or environmental conditions require field welding.

Groove Welds (Butt Joints)

These welds are typically used for plates or structural members joined edge to edge.

5. Full Penetration Single V Butt Weld

- Visual: One side is beveled like a “V”.

- Symbol: V symbol with filled root.

- Use: High-strength welds in thicker material. Ensures complete fusion from top to bottom.

6. Full Penetration Double V Butt Weld

- Visual: Both sides are beveled, forming a double-V.

- Symbol: Two V symbols with filled roots.

- Use: Preferred for thicker materials where welding from both sides is possible. Reduces distortion.

7. Full Penetration Double Bevel Butt Weld

- Visual: Similar to double V but with straight bevels instead of angled.

- Symbol: Two straight bevel lines.

- Use: Often used when machining bevels is easier or more practical than creating a V groove.

Partial Penetration Groove Welds

Not every job needs full penetration. These partial welds are quicker and cheaper — good for when full strength isn’t necessary.

8. Partial Penetration Y Weld

- Visual: One side beveled with limited depth penetration.

- Symbol: A Y shape.

- Use: Used in structural work where appearance or load isn’t critical, but strength still matters.

9. Partial Penetration Half Y Weld

- Visual: Shallower version of the Y weld.

- Symbol: Shorter Y symbol.

- Use: Used in sheet metal or light structural connections where minimal penetration is enough.

10. Partial Penetration Square Butt Weld

- Visual: No groove prep; just welded at the seam.

- Symbol: Straight line with hatching.

- Use: Thin plates or fast welds where penetration isn’t a concern. Not ideal for high-stress areas.

11. Full Penetration Square Butt Weld

- Visual: Clean edge-to-edge joint with full fusion.

- Symbol: Straight line, no bevel or V.

- Use: Often used in automation, where edge prep and full pen are possible without beveling.

Why These Symbols Matter

Each of these weld symbols tells the welder or fabricator exactly:

- What type of weld to use

- Where to place it

- How it should look (profile, size, and extent)

Misreading or ignoring these symbols can lead to structural failures, inspection failures, or rework that kills a project timeline and budget.

Quick Tips for Interpreting Weld Symbols

- The arrow side of the joint is always the reference point.

- Symbols below the line apply to the arrow side.

- Symbols above the line apply to the opposite side.

- A filled-in symbol usually means full penetration or completed weld.

- Additional flags, circles, or notes modify the requirement (e.g., all-around, field weld).

Final Thoughts

Understanding weld symbols is more than just a box you check for certification — it’s part of what makes you a professional in this trade. Whether you’re running beads in the shop or bidding on a structural contract, knowing the difference between a Y weld and a full-pen V groove is critical.

Print this chart, study the symbols, and keep it nearby. You’ll move faster on blueprints, communicate better with inspectors, and avoid those “I thought you meant…” moments.

Affiliate Disclosure: This post may contain affiliate links. We may earn a commission from qualifying purchases — at no cost to you — which helps support the blog and content creation.

Leave a Reply