Auto-darkening helmets protect your eyes by switching from light to dark state when arc strikes. Choosing the right one depends on lens speed, shade range, viewing area, and certification—not brand hype.

Key Specifications

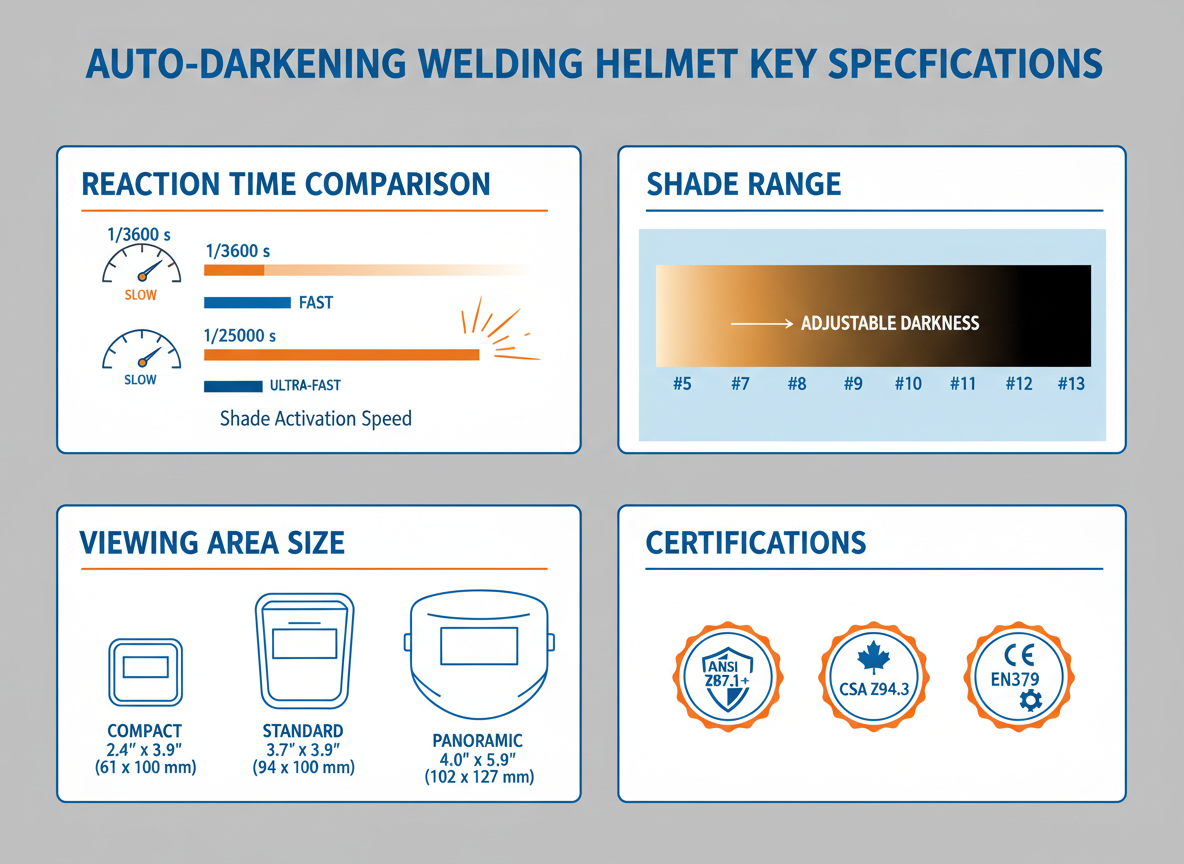

Reaction Time (Switching Speed)

| Level | Speed | Decimal |

|---|---|---|

| Entry-level | 1/3600 second | 0.00028s |

| Mid-range | 1/10000 second | 0.0001s |

| Professional | 1/25000 second | 0.00004s |

TIG welding requires faster response (1/20000s minimum) due to low-amperage arc initiation. MIG and stick work fine with 1/10000s.

Shade Range

- Standard range: #9–#13

- TIG-specific: #5–#13 (low-amp visibility)

- Grinding mode: #3–#4 (light state)

AWS D1.1 requires minimum shade #10 for 60–160A stick welding, #11 for 160–250A, #12 for 250–550A.

Viewing Area

| Size | Dimensions | Area |

|---|---|---|

| Compact | 3.5” × 1.65” | 6 sq in |

| Standard | 3.93” × 2.36” | 9.3 sq in |

| Wide-view | 3.93” × 2.87” | 11.3 sq in |

| Panoramic | 4.25” × 3.25” | 13.8 sq in |

Larger viewing area improves peripheral awareness in tight spaces and multi-pass work.

Optical Clarity Rating (1/1/1/1 to 1/1/1/3)

Four numbers indicate: optical class / light diffusion / variations in luminous transmittance / angle dependence.

- 1/1/1/1 = highest clarity (minimal distortion)

- 1/1/1/2 = professional grade

- 1/1/1/3 = acceptable for general fabrication

Certification Requirements

ANSI Z87.1+ (High-Impact Rated)

Required for all industrial welding environments. Plus symbol (+) indicates high-velocity impact protection.

CSA Z94.3

Canadian standard equivalent to ANSI Z87.1+.

EN379

European standard covering optical class, switching time, and UV/IR protection.

Process-Specific Requirements

TIG (GTAW)

- Reaction time: 1/20000s or faster

- Shade range: #5–#13 (low-amp start visibility)

- Sensitivity adjustment: Essential for low-amperage starts

MIG (GMAW)

- Reaction time: 1/10000s acceptable

- Shade range: #9–#13

- Spatter resistance: Check lens cover plate availability

Stick (SMAW)

- Reaction time: 1/10000s acceptable

- Shade range: #10–#13

- Grinding mode: Useful for slag removal between passes

Flux-Core (FCAW)

- Same as MIG requirements

- Higher spatter = more frequent cover plate replacement

Power Source Options

Solar-powered

- Pros: No battery replacement, lighter weight

- Cons: Requires adequate light exposure, slower recovery in dim environments

Battery-powered

- Pros: Consistent performance in all lighting

- Cons: Battery replacement every 6–12 months (CR2032 or AAA)

Solar + Battery Hybrid

- Best reliability for production environments

- Battery backup prevents downtime

True Color vs. Standard Lens Technology

| Feature | Standard Green Lens | True Color Lens |

|---|---|---|

| Color perception | Green/blue tint | Natural color |

| Weld pool visibility | Adequate | Enhanced |

| Heat color distinction | Standard | Superior |

| Cost | Base price | 2–3× premium |

| Best for | Structural steel | Stainless/aluminum TIG |

True color improves precision on stainless and aluminum TIG work but isn’t necessary for structural steel fabrication.

Buying Checklist

- ✓ ANSI Z87.1+ certification marked on helmet

- ✓ Reaction time matches your primary process

- ✓ Shade range covers your amperage requirements

- ✓ Viewing area suits your work environment

- ✓ Optical clarity rating 1/1/1/2 or better

- ✓ Replacement lens covers readily available

- ✓ Adjustable sensitivity and delay controls

- ✓ Grinding mode if you do stick or flux-core

Common Mistakes

Buying based on viewing area alone

Large viewing area with slow reaction time = retina damage risk. Verify switching speed first.

Ignoring optical clarity rating

1/1/1/3 lenses cause eye strain during 8+ hour shifts. Pay for 1/1/1/2 if you weld full-time.

Skipping sensitivity adjustment testing

Low-amperage TIG (10–40A) won’t trigger poorly calibrated sensors. Test before buying.

Leave a Reply