Check out the Strong Hand Tools Store

A solid welding table setup is the foundation of quality work in any metal fabrication shop. But in today’s fast-paced environments, fixed tables and ad hoc clamps don’t cut it anymore, especially when you’re building repeatable or complex assemblies. That’s where modular fixturing systems, like those from Strong Hand Tools, come into play.

Modular welding tables are engineered for flexibility, speed, and accuracy. These setups allow welders to fixture, tack, weld, and inspect parts on the same table—all while maintaining tight tolerances.

Who’s this for?

If you’re a production welder, custom metal fabricator, robotic welding tech, or industrial engineer setting up jigs, you’ll benefit from learning how modular fixturing works and why Strong Hand’s system is one of the most widely used in the industry.

Types of Modular Welding Table Systems

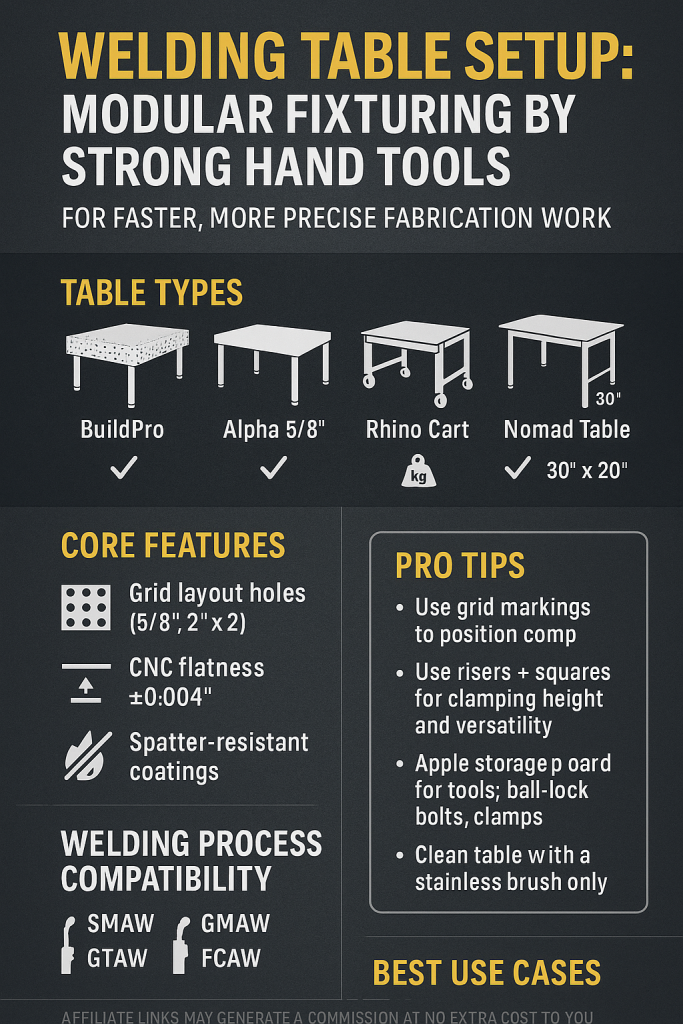

Strong Hand Tools offers multiple systems to fit a range of shop needs and budgets. Each variant has its own use case and is built around a precision-ground tabletop with a grid of holes and slotted surfaces for accessories.

BuildPro® Welding Tables

- Heavy-duty fabrication system

- 5/8″ or 16 mm hole diameter (metric and imperial)

- For custom builds, jigs, and high-precision projects

- Compatible with over 200+ fixturing elements

Alpha 5/8″ System

- Premium, fully modular system with hardened tops

- CNC-machined flatness tolerance (±0.004″)

- Suited for aerospace, automation, and robotic welding cells

Nomad™ Tables

- Entry-level portable table

- Ideal for field repairs or small-shop fabricators

- Folding legs, adjustable height, and built-in clamps

- Not truly modular, but supports light-duty clamping

Rhino Cart® Fixturing Station

- All-in-one mobile cart/table system

- Includes a 36″ x 24″ tabletop and starter fixturing kit

- Perfect for shops with space constraints or mobile setups

- The Rhino Cart all-in-one Mobile Welding Cart puts both roomy tool storage space and a large work

- Reversible tabletop with nitrided black oxide protective finish for wear, rust, and weld spatter resistance.

- Steel legs are equipped with four locking casters and leveling feet for mobile or stationary use.

- Welding Table, 48″ x 30″ , 36″ height, 5/8″ thickness, ∅5/8″ hole, 2″ x 2″ grid pattern, 1500 lb. static loading capacity.

Last update on 2026-02-20 / Affiliate links / Images from Amazon Product Advertising API

Key Characteristics & Properties

Precision & Flatness

- CNC-machined surfaces ensure high repeatability for complex jigs

- Flatness tolerance is as tight as ±0.004″ over the entire surface (Alpha Series)

Modular Hole Pattern

- Tables use grid layouts (e.g., 2″ x 2″ spacing or 50 mm metric) for plug-and-play setups

- Compatible with V-blocks, risers, stops, clamps, and corner squares

Load Capacity

- BuildPro and Alpha tables support over 2,000 lbs

- Tables are constructed with hardened steel or nitrided surfaces to resist spatter and distortion

Materials & Coatings

- Tabletops are made from HRPO steel or nitrided steel (Alpha) to withstand high heat

- Optional leg leveling kits or casters provide mobility and adjustability

Process Considerations

SMAW / Stick Welding

- Works best with heavy plate or pipe welding

- Modular stops and risers help fix bulky parts

GMAW / MIG Welding

- Clamping and fixturing tools reduce heat distortion during tacking

- Magnetic clamps and shielding accessories can be added for safety

GTAW / TIG Welding

- Requires clean, flat, non-contaminated surfaces

- Strong Hand nitrided tables resist oxide buildup and heat transfer

FCAW / Flux-Core Welding

- Heavy-duty jigs and 3D fixturing arms allow out-of-position welding

- Ideal for structural or tubular setups in modular frame builds

Tip: Always ground your welding lead to the table using the dedicated ground slots or pads for clean arc initiation.

Application Use Cases

Fabrication Shops

- Frame welding, brackets, gates, and repeatable weldments

- Reduce downtime between builds with reusable jigs

Robotic Welding Cells

- Alpha 5/8″ system integrates easily with robot bases or rails

- High accuracy allows robots to follow pre-programmed weld paths

Schools & Training Labs

- Rhino Cart or Nomad tables are budget-friendly but still teach fixturing fundamentals

Aerospace, Automotive, Structural

- Table risers, V-blocks, and toggle clamps support precision weldment setups

- Common in fixture-based production, such as chassis or pipe assembly

Best Practices & Pro Tips

- Mark your jigs for repeatability—use the table’s grid numbering system

- Pre-fit your parts dry before welding to confirm alignment and clearance

- Use spring-loaded clamps for fast setups without tool marks

- Clean the tabletop regularly with a stainless brush—no grinding wheels

- Store your modular tools in labeled bins or magnetic boards to save time

Pro Setup: Use angle squares and stop blocks to quickly align corners at 90°, 45°, or custom angles without measuring.

Conclusion

Strong Hand’s modular welding table systems are more than just flat surfaces—they’re productivity machines. Whether you’re running a full-blown fab shop or just starting out, having a modular fixturing setup means tighter tolerances, fewer mistakes, and faster builds.

Bottom line? If you weld for production or precision, a modular fixturing system like BuildPro or Alpha should be on your shortlist. They make setup smarter, not harder.

Check out the Strong Hand Tools Store

Affiliate Disclosure

Some of the links in this article may be affiliate links, which means we may earn a commission if you purchase through them—at no extra cost to you. Your support helps us continue providing quality welding education.

Leave a Reply