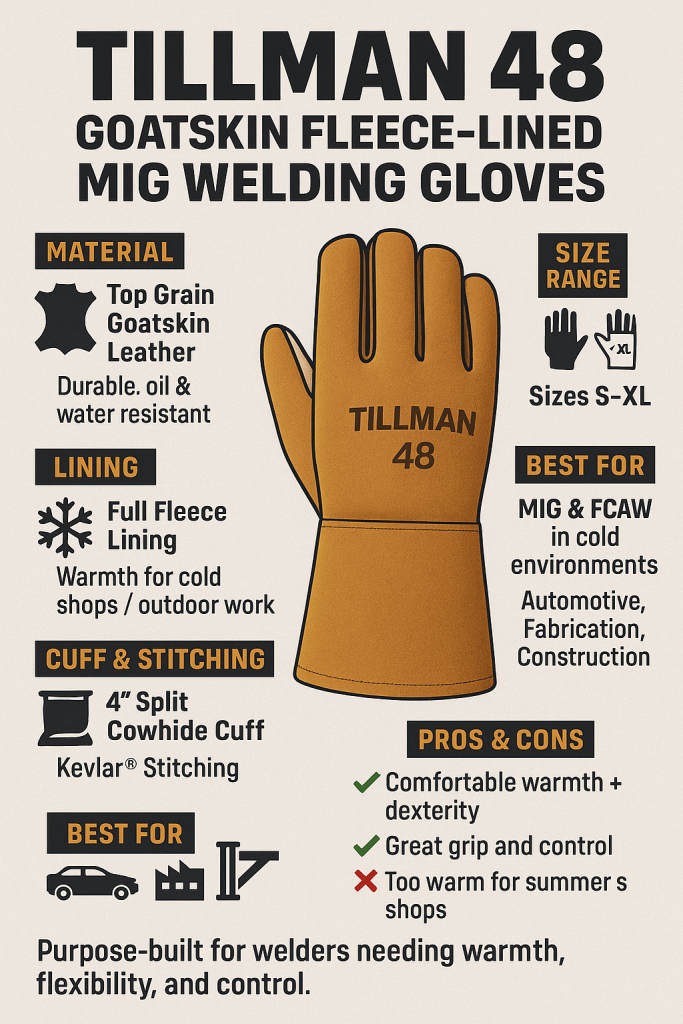

Product Review: Tillman 48, Goatskin Fleece-Lined Standard Grade MIG Gloves

Tillman 48, Goatskin Fleece Lined Standard Grade MIG Gloves are a specialized type of protective apparel engineered for MIG (Metal Inert Gas) welding applications. Constructed with premium goatskin leather and enhanced with fleece insulation, these gloves are tailored for welders who need a combination of mobility, dexterity, and thermal protection.

Designed for the professional welder, fabrication student, or anyone working in moderate to heavy-duty welding environments, these gloves are a go-to solution for consistent, comfortable hand protection during extended welding sessions.

Types / Variants / Models

The Tillman 48 is a model within Tillman’s line of MIG gloves specifically built for winter or cold shop environments. While the model itself doesn’t come with multiple variants, it can be contrasted with other Tillman MIG glove lines to show its distinct place in the market:

-

Tillman 42 (Unlined MIG Glove)

- Made from top-grain goatskin but unlined, offering better heat dissipation but less warmth.

- Best for moderate climates or short arc runs.

- Price For: Each Stitching Material: Kevlar(R) Grade of Leather: A Design: (2) Piece Back Item: Welding Gloves Size: L Color: Tan Cuff Material: Split Cowhide Leather Lining Material: Cotton/Foam Length: 12″ Cuff: 4″ Gauntlet Cut: Gunn Thumb Style: Reinforced Application: MIG Back Material: Grain Pigskin Palm Material: Pigskin

- Leather Palm Type: Top Grain Country of Origin (subject to change): Unknown

Last update on 2026-01-19 / Affiliate links / Images from Amazon Product Advertising API

-

Tillman 875 (Top Grain Pigskin)

- Features fleece lining, but made of pigskin for higher oil resistance.

- Ideal for oily environments or when working with oily metals.

- Package Dimension : 7.7 centimeters L x 18.2 centimeters W x 29.1 centimeters H

- Item Package weight : 0.276 kilograms

- Made in: United States

- Straight thumb with added reinforcement

Last update on 2026-01-19 / Affiliate links / Images from Amazon Product Advertising API

-

Tillman 1350 (Top Grain Cowhide)

- Includes Kevlar lining for added cut resistance.

- Suitable for jobs with high abrasion risk.

- Welders Gloves

- Manufacturer: John Tillman & Co

- Made in: United States

- Heavy duty pearl top cowhide

Last update on 2026-01-19 / Affiliate links / Images from Amazon Product Advertising API

Tillman 48 stands out due to its fleece lining and goatskin composition, making it ideal for cold-weather shops and increased dexterity needs.

Key Features & Specifications

Here’s a breakdown of the Tillman 48 MIG gloves’ key physical and technical specifications and their benefits:

-

Material: Top grain goatskin leather (palm and back)

- Delivers exceptional dexterity and tactile control.

- Naturally oil- and water-resistant.

-

Lining: Fleece lining throughout

- Provides insulation against cold environments, ideal for outdoor or unheated shop work.

- Adds comfort over extended wear.

-

Cuff style: 4” split cowhide cuff

- Ensures added wrist and forearm protection against sparks and slag.

- Stiffness in cuff makes it easier to slide gloves on/off.

-

Stitching: Kevlar® thread

- Offers high heat and abrasion resistance, minimizing seam failure under welding conditions.

-

Size Range: Available in sizes S – XL

- Accommodates a broad range of hand sizes for optimal fit and performance.

-

Certifications:

- While the Tillman 48 does not carry an ANSI or CE cut rating, it complies with general industrial PPE guidelines for welding heat protection.

These specs make it especially suitable for welders seeking mobility without sacrificing crucial thermal and mechanical protection.

Usage & Compatibility

The Tillman 48 is designed primarily for MIG (GMAW) welding but can also be used selectively in other processes with similar handling requirements:

- GMAW (MIG): Ideal for moderate heat levels over long periods—offers the dexterity required to guide the gun with precision.

- FCAW (Flux-Cored Arc Welding): Suitable, especially in colder environments, for additional hand warmth.

- SMAW (Stick Welding): Usable for lower-amperage stick work, but lacks the padding needed for high-amperage stick or gouging.

- GTAW (TIG): Not recommended due to reduced fingertip feel; TIG work typically requires thinner, unlined gloves.

Pros:

- Excellent grip and tactile control.

- Comfortable during prolonged use.

- Thermal insulation without excessive bulk.

Cons:

- Not flameproof or cut-rated to ANSI A-levels.

- Fleece lining may be too warm for summer or high-temperature indoor shops.

- Not suitable for high-heat stick or overhead MIG applications.

Common Applications

The Tillman 48 Goatskin Fleece-Lined MIG Gloves are suitable for:

- Outdoor fabrication yards: Welders working in sub-freezing temperatures benefit from the warmth and dexterity combo.

- Automotive repair/production: Where sustained hand protection and feel for fine MIG passes are vital.

- Metal art and sculpture fabrication: Delicate but repetitive welds where hand fatigue is a risk.

- Steel building construction and repair: Offers protection and comfort for field welders wearing gloves all day.

The glove’s design makes it ideal for moderate-duty welders who frequently need to handle sheet metal, round tubing, or small-fillet MIG joints without overheating or over-bulking.

Tips & Best Practices

To maximize glove performance and life:

- Break-in Tip: Like most goatskin gloves, the fit improves slightly after break-in. Wear them around the shop before performing precision work.

- Storage: Keep gloves dry and clean; fleece lining may retain sweat or moisture if stored improperly.

- Cleaning: Spot-clean leather with a damp cloth. Do not machine wash—this can shrink leather and warp fleece.

- Don’t Overuse in High Heat: While durable, the fleece liner can melt under extreme flame or slag exposure. If welding over 250A GMAW or full-penetration stick, use gloves rated for high heat.

Common Mistakes to Avoid:

- They are used in high-heat gouging or carbon arc operations where heavy-duty cowhide is preferable.

- Wearing them for TIG without switching to thinner gloves results in poor arc control.

Conclusion

The Tillman 48 Goatskin Fleece-Lined Standard Grade MIG Gloves are a high-value option for welders working in colder or unheated environments who require a balance between warmth, flexibility, and fine control. They excel in MIG and light flux-core work—particularly when dexterity and thermal comfort are crucial—and are well-suited for welders, students, and professionals across fabrication, auto repair, and construction industries.

Key takeaway: If you’re welding in cold climates or need sensory control without sacrificing finger flexibility, the Tillman 48 is a smart, purpose-built solution.

This post may contain affiliate links. If you purchase through them, we may earn a small commission at no cost to you. Thank you for supporting our site.

- Welders Gloves

- Manufacturer: John Tillman & Co

- Made in: United States

- Thumb Elastic Back Glove Mig/Tig Medium Goatskin Palm Cowhide Split Back With Straight

Last update on 2026-01-19 / Affiliate links / Images from Amazon Product Advertising API

- A top grain goatskin palm for best feel

- MIG Welding appliations

Last update on 2026-01-19 / Affiliate links / Images from Amazon Product Advertising API

- Price For: Each Stitching Material: Kevlar(R) Grade of Leather: A Item: Welding Gloves Size: XL Color: Pearl Cuff Material: Split Cowhide Leather Lining Material: Fleece Length: 13″ Cuff: 3-1/2″ Gauntlet Cut: Gunn Thumb Style: Straight Application: MIG/TIG Back Material: Split Cowhide Palm Material: Goatskin Leather Palm Type: Grain

- Country of Origin (subject to change): China

Last update on 2026-01-19 / Affiliate links / Images from Amazon Product Advertising API