Note for Readers: This post may contain affiliate links. If you purchase through them, we may earn a small commission at no cost to you. Thank you for supporting our site.

Introduction

The Weldtec Speedway SW-320-25DX Deluxe Water-Cooled TIG Torch Kit, 25’, Braided is a professional-grade TIG torch engineered for high-performance gas tungsten arc welding (GTAW). Built for demanding applications, this 320-amp water-cooled torch ensures excellent thermal management during extended welding at high amperages.

The 25-foot braided cable delivers greater maneuverability and durability compared to standard rubber leads, making this kit a favorite for welders who need precision, comfort, and consistent performance.

This kit is popular with:

- Structural welders

- Aerospace and automotive fabricators

- Welding instructors and advanced students

- Engineers and metal artists working with stainless steel, titanium, and aluminum

If you perform long welding passes, work on heat-sensitive materials, or weld in tight positions, the SW-320-25DX offers the cooling, flexibility, and reliability to get the job done.

Types / Variants / Models

Weldtec offers multiple Speedway torch kits designed for different amperage ranges and cooling methods:

- SW-320-25DX (this model):

- Water-cooled, 320 amps, 25’ braided cable

- Ideal for heavy-duty industrial TIG welding

- SW-225-25DX:

- Similar design but rated for 225 amps

- Suited for mid-range applications and lighter gauges

- Air-Cooled Speedway Torches:

- Up to ~150 amps

- Practical for fieldwork or short-duration jobs without water cooling

- Rubber Hoses:

- Heavier and less flexible than braided lines

- More abrasion-resistant in rough shop environments

Choose the SW-320-25DX if you need high heat input, long duty cycles, and superior cooling when working with specialty alloys.

Key Features and Specifications

The SW-320-25DX Deluxe kit combines durability and ergonomic design for professional welders.

- Amperage Rating

- 320A DC, 250A AC @ 100% duty cycle

- Suitable for thick materials, structural welding, and long arcs without overheating

- Cooling System

- Water-cooled torch head and hoses

- Runs cooler, extending service life

- Note: Some kits include quick-connects, but these may be optional depending on supplier

- Cable Assembly

- 25’ braided nylon composite lead

- Lightweight, flexible, and kink-resistant — excellent for bench or out-of-position welding

- Torch Head

- Speedway design promotes smoother shielding gas flow and easier arc starts

- Compatible with standard 3-series (WP-20 style) consumables

- Handle Design

- Slim knurled body provides grip and control

- Reduces fatigue over long sessions

- Connections

- Standard 5/8″-18 RH fitting for gas

- Power adapter included for most TIG power sources (check fitting size for your machine)

- Manufacturing Standards

- Made in the USA

- Built to meet industry standards for welding reliability and safety

Usage & Compatibility

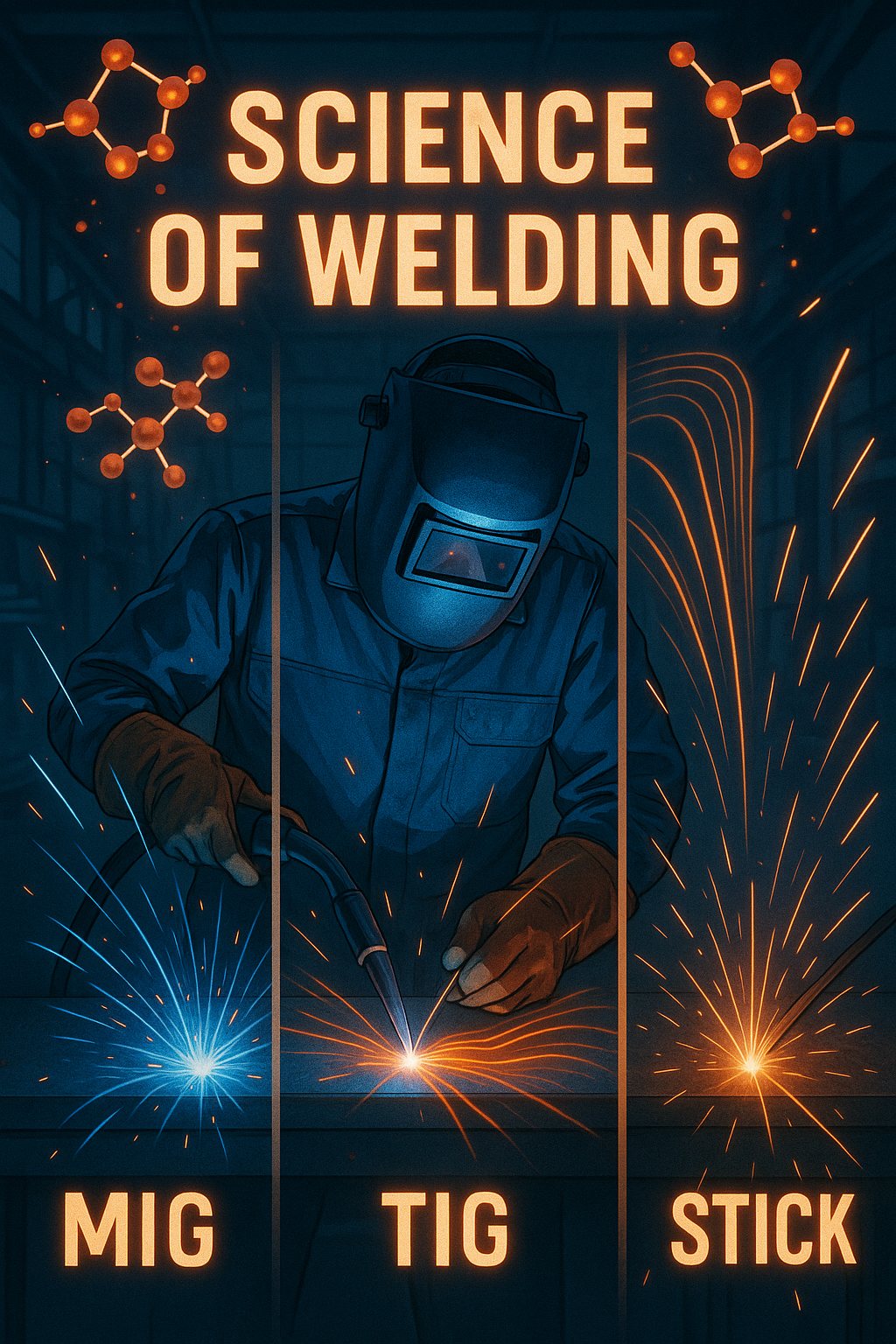

This torch is designed specifically for GTAW (TIG) welding. It’s not interchangeable with SMAW, GMAW, or FCAW processes.

Compatibility Highlights:

- Works with most AC/DC TIG machines rated 300A+ with water coolers

- Fits many Miller, Lincoln, ESAB, and Everlast units

- Adapter fittings may be required, depending on your power source and cooler connections

User Experience Notes:

- Runs noticeably cooler with a quality water cooler (e.g., Coolmate, Dynaflux)

- Braided cable flexibility reduces fatigue in fabrication shops

- Arc starts are stable thanks to Speedway’s internal gas flow design

Common Applications

The SW-320-25DX is trusted across a variety of industries:

- Aerospace fabrication & repair – precision TIG on titanium and stainless

- Automotive fabrication – chromoly roll cages, stainless exhausts, aluminum intercoolers

- Manufacturing & metal art – clean welds with minimal post-processing

- Sanitary stainless piping – consistent arcs for food and pharmaceutical work

- Education & certification programs – teach proper technique on pro-grade gear

Tips & Best Practices

Setup:

- Use distilled water or approved coolant to prevent corrosion

- Route coolant return lines above torch level to prevent backflow

- Secure braided cable with strain reliefs to avoid abrasion

Usage:

- Match tungsten type to job (e.g., 2% lanthanated for general use)

- Adjust the AC balance carefully when welding aluminum

Maintenance:

- Inspect the torch neck, handle, and hoses regularly for wear

- Clean the gas lens and collet body to maintain smooth arc initiation

Troubleshooting:

- If overheating, check the coolant level and purge air from the system

- If the arc is unstable, replace worn consumables and check ground clamp

Conclusion

The Weldtec Speedway SW-320-25DX Deluxe Water-Cooled TIG Torch Kit delivers reliable performance, superior cooling, and operator comfort for demanding TIG applications. With its flexible braided cable, ergonomic design, and professional build quality, it’s a smart investment for welders who need precision and durability.

Whether you’re fabricating aerospace components, tuning a chromoly chassis, or teaching advanced GTAW techniques, the SW-320-25DX stands out as a dependable, professional-grade torch kit.

- Maximum Amperage Capacity (ac-dcsp) 320 AMPS

- Weight (Torch Body and Handle) 3.0 oz (84 gm)

- Tungsten Size Capacity .020″ – 5/32″ (0.5 – 4,0mm)

- Maximum Tungsten Length 7″ (178mm)

- Cooling Requirements 1 QT./min (.946 L/min) @ 50 PSI

Last update on 2026-02-22 / Affiliate links / Images from Amazon Product Advertising API

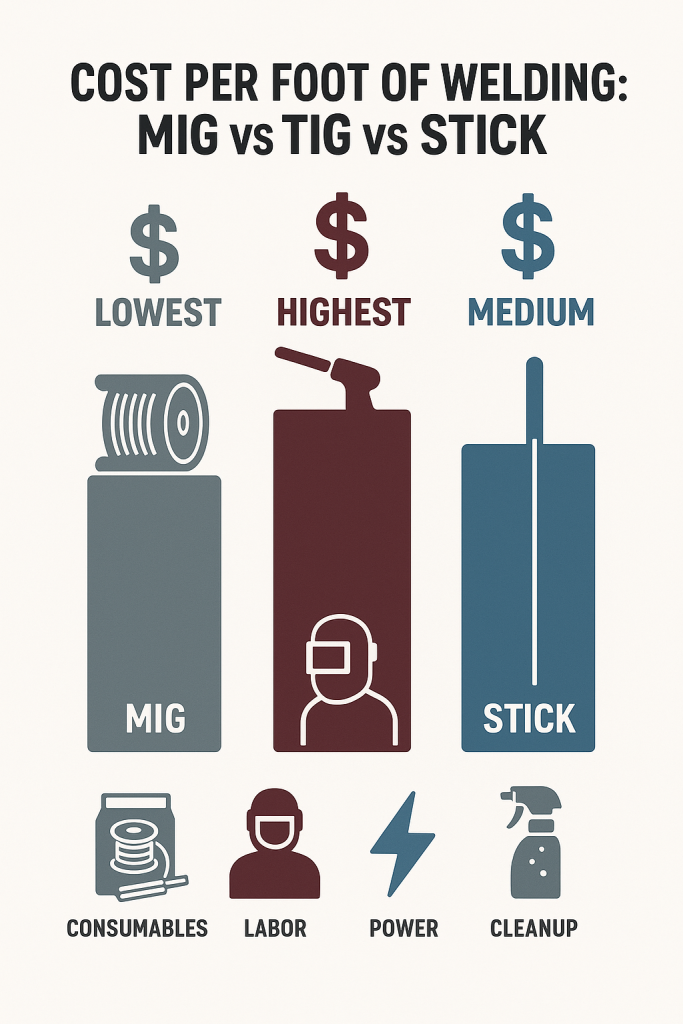

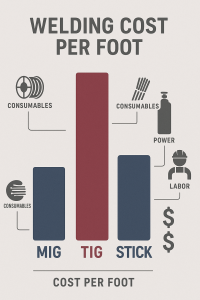

MIG Welding (GMAW) – High Speed, Low Cost

MIG Welding (GMAW) – High Speed, Low Cost

Assumptions:

Assumptions: MIG Welding Cost Example

MIG Welding Cost Example $0.89/ft

$0.89/ft