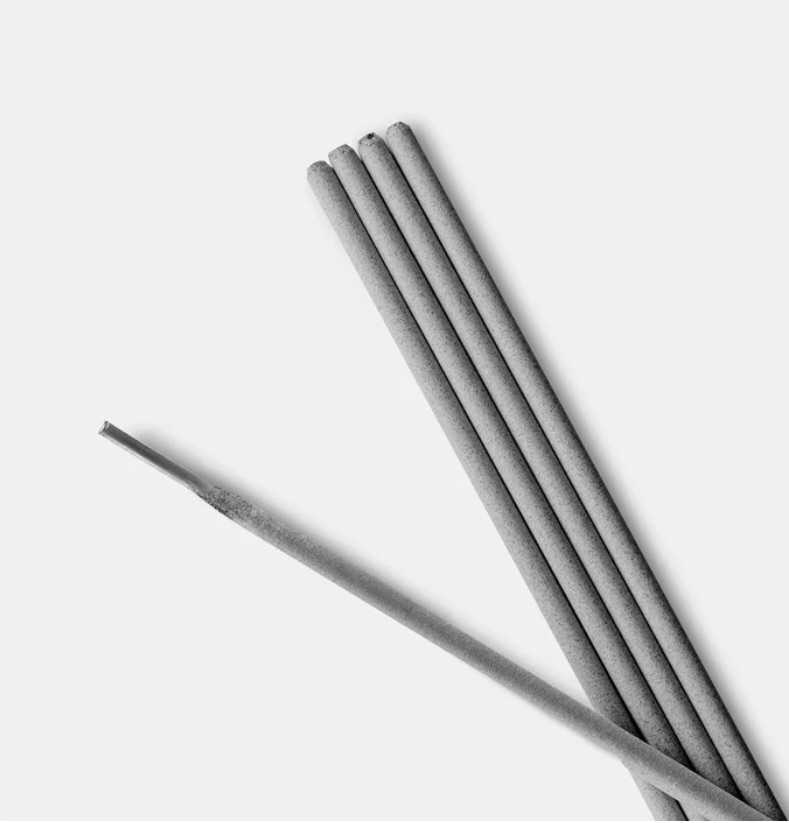

Nickel 55 MIG welding wire is a specialized filler metal designed for welding cast iron and joining dissimilar metals. Composed of approximately 55 % nickel and 45 % iron, it provides a strong balance of ductility, strength, and machinability—qualities that are difficult to achieve with standard welding wires.

This filler wire is ideal for repairing cast iron components where post-weld machining is required. It’s widely used by welders, fabricators, engineers, and technicians working on engines, gearboxes, pumps, and heavy machinery.

Types / Variants / Models

Although “Nickel 55” refers to its nickel-iron ratio, different versions exist depending on brand and application:

Common Diameters

-

0.035” (0.9 mm): for light- to medium-duty work

-

0.045” (1.14 mm): for thicker sections and deeper penetration

-

1/16” (1.6 mm): for heavy-duty or industrial repair

Spool Sizes

-

1 lb, 10 lb, and 20 lb spools for small jobs or continuous production

-

Straight lengths (for TIG use) – rare, but available for hybrid setups

Core Types

-

Solid wire (ERNiFe-CI): the standard for MIG welding

-

Flux-cored nickel wire – less common, used outdoors or on dirty metal

Choose the variant that best matches your base metal, machine setup, and project size.

Key Features & Specifications

| Specification | Detail |

|---|---|

| Composition | ~55 % Nickel, balance Iron |

| Benefit | Reduces cracking and porosity; easy post-weld machining |

| AWS Classification | ENiFe-CI / ERNiFe-CI |

| Tensile Strength | ≈ 70,000 psi |

| Current Type | DCEP (Direct Current Electrode Positive) |

| Compatibility | Standard MIG guns and wire feed systems |

| Shielding Gas | 100 % Argon or 75 % Argon / 25 % CO₂ |

| Packaging | Copper-coated spools to improve feed and reduce oxidation |

These specifications make Nickel 55 wire an excellent all-around solution for cast iron repair and high-strength applications.

Usage & Compatibility

Nickel 55 wire is primarily used with GMAW (MIG) equipment featuring constant-voltage (CV) power supplies.

Welding Processes

-

MIG (GMAW): primary use

-

Stick (SMAW): use nickel stick rods instead

-

TIG (GTAW): requires matching rod form

-

Flux-Core (FCAW): possible with nickel flux-cored wire

Pros

-

Excellent fusion with cast iron

-

Reduced hot cracking and porosity

-

Machinable weld beads and strong mechanical properties

Cons

-

More expensive than mild steel wire

-

Requires proper preheat and slow cooling

-

Less effective on oil-soaked castings without thorough cleaning

Common Applications

Nickel 55 MIG wire is used in industries where cast iron repairs demand both strength and machinability:

-

Engine blocks and cylinder heads

-

Gear housings and pumps

-

Machinery bases and frames

-

Exhaust manifolds and heat-affected parts

-

Farm and construction equipment repairs

Its nickel-iron composition provides crack resistance and durability under vibration and heat.

Tips & Best Practices

-

Preheat to 250–600 °F to reduce thermal stress

-

Cool slowly (blanket wrap or bury in sand) to prevent cracks

-

Clean the base metal thoroughly (oil, paint, rust removed)

-

Weld short passes and peen between passes to release stress

-

Store wire dry to avoid oxidation and feeding issues

-

Match shielding gas (100 % Argon gives cleanest arc)

-

Inspect welds for porosity before machining or load service

Conclusion

Nickel 55 MIG welding wire is an essential filler for any welder who repairs cast iron or dissimilar metals.

Its 55 % nickel composition provides superior crack resistance and machinability, making it the preferred choice for engine blocks, gear housings, and industrial repairs where durability matters.

If you routinely work with cast iron or machined components, Nickel 55 wire is a smart investment for long-term performance and precision.

Where to Buy Nickel 55 MIG Welding Wire

You can find Nickel 55 MIG wire from verified Amazon sellers and welding-supply distributors.

Use the link below to check current price and availability:

Last update on 2025-12-05 / Affiliate links / Images from Amazon Product Advertising API

Last update on 2025-12-05 / Affiliate links / Images from Amazon Product Advertising API

Last update on 2025-12-05 / Affiliate links / Images from Amazon Product Advertising API

Affiliate Disclosure

This post contains affiliate links. If you purchase through these links, we may earn a small commission at no additional cost to you. This helps us maintain our site and continue producing helpful welding guides.

Leave a Reply