TIG (GTAW) welding is all about precision, and one often-overlooked component that plays a huge role in weld quality is the TIG cup. Whether you’re using ceramic or glass, choosing the correct cup size directly affects shielding gas flow, arc stability, and weld bead appearance.

This guide is designed for professional welders, welding students, and metal fabricators who want to understand how to select the best cup for their specific application, whether working with stainless steel pipe or aluminum sheet.

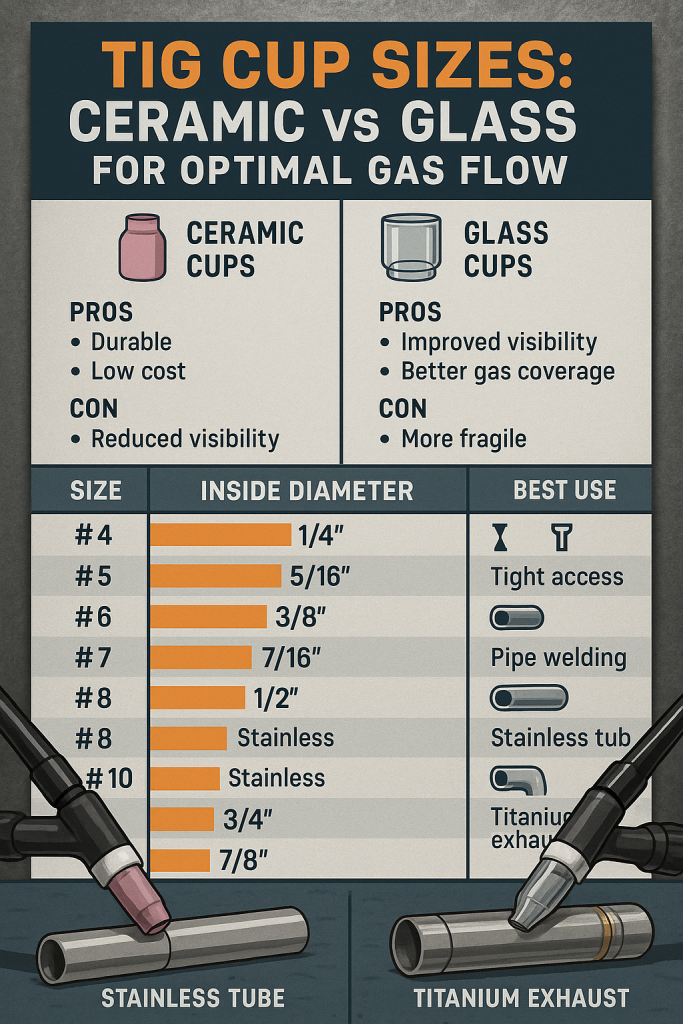

Types of TIG Cups: Ceramic vs. Glass

There are two primary types of TIG cups used today:

1. Ceramic (Alumina) Cups

- The most common material for TIG cups

- Durable and resistant to heat

- Standard for general fabrication work

- Inexpensive and widely available

2. Glass (Pyrex) Cups

- Transparent—great for visibility of the weld puddle

- Popular with pipe welders and instructors for live arc teaching

- Fragile compared to ceramic

- Often used with gas lens setups

Common TIG Cup Sizes and Applications

Cup sizes range by number, which corresponds roughly to 1/16” per number unit in inside diameter. Example: Size #6 = 3/8″.

Here’s a breakdown:

| Cup Size | Material | Best Use Cases |

|---|---|---|

| #4 (1/4″) | Tight access work, very low amperage welding | Tight joint access, low-amp precision work, thin sheet metal (e.g., 18–22 gauge stainless or aluminum) |

| #5 (5/16″) | Thin materials, short weld runs | Low to mid-amp welds on light gauge materials, automotive panels, bike frames |

| #6 (3/8″) | General purpose TIG work, mild steel or aluminum | General fabrication on mild steel, aluminum, and stainless; good all-purpose cup for shop work |

| #7 (7/16″) | Better gas coverage, moderate to high amps | Improved gas coverage for slightly larger welds; good for stainless tube work, aluminum brackets |

| #8 (1/2″) | Stainless steel pipe, titanium, or reactive metals | Pipe welding, stainless tanks, titanium tubing—any application requiring extra shielding gas |

| #10–#12 | Extra gas coverage, large fillets, aerospace jobs | Reactive metals, large fillet welds, parts needing wider gas shield; often paired with gas lens |

| #14+ (1”+) | High-purity work, exotic metals, walk-the-cup pipe welding | Reactive metals, large fillet welds, parts needing wider gas shield, often paired with gas lens |

Key Characteristics to Understand

1. Shielding Gas Coverage

- Larger cups distribute argon more broadly and evenly, reducing atmospheric contamination on metals such as stainless steel and titanium.

- Smaller cups concentrate flow—better for detail work, but risk poor shielding on wide welds.

2. Gas Lens Compatibility

- Use gas lens collet bodies with larger or glass cups to improve laminar flow.

- Allows for extended tungsten stick-out without turbulence or contamination.

3. Visibility & Puddle Control

- Glass cups give you complete visibility—ideal when puddle control is critical.

- Ceramic cups block your side view, but retain better durability.

4. Heat Resistance & Durability

- Ceramic: Superior for high-amp, long-run welding.

- Glass: Requires careful handling and is susceptible to cracking.

Process Considerations

GTAW (TIG Welding)

- TIG is the only process where cup selection dramatically affects weld quality.

- High-amperage aluminum welding needs a larger cup to avoid contamination.

- DC welding of mild steel typically works well with #6 or #7 ceramic cups.

Welding Equipment Compatibility

- Make sure your torch head (typically WP-17, WP-20, or WP-9) accepts your chosen cup and collet body.

- Glass cups often require aftermarket torch kits or stubby gas lens kits.

Application Use Cases

Common Projects & Metals:

- Stainless steel tubing (e.g., food-grade pipe): Use #8+ gas lens glass cup

- Mild steel fabrication (e.g., brackets, frames): Use #6–#7 ceramic

- Aluminum TIG (e.g., auto parts): Use larger ceramic cup with high CFH

- Titanium or exotic alloys (e.g., aerospace, motorsports): Use #12+ glass with gas lens and trailing shield

Industries That Care About Cup Selection:

- Aerospace & Motorsport Fabrication

- Food and Beverage Stainless Systems

- General Repair Shops and Field Welders

- Welding Schools & Training Facilities

Best Practices & Pro Tips

- Use a gas lens for smoother flow and larger tungsten stick-out—it makes a world of difference with larger cups.

- Flow rate matters: Larger cups may require 25–35 CFH; too little gas and your weld oxidizes.

- Don’t overtighten glass cups—they can shatter under torch heat expansion.

- For thin aluminum or sheet metal, a #5 or #6 ceramic is usually all you need.

- Instructing or filming welds? Use Pyrex to help show arc and puddle behavior clearly.

Safety Note

Always wear proper shade protection, especially when using glass cups, which do not block stray light like ceramic. The arc is more visible, and that includes UV exposure.

Conclusion

Choosing the right TIG cup size and material—ceramic or glass—can significantly impact gas shielding, arc control, visibility, and ultimately, your weld quality. For general fabrication, stick with ceramic cups in the #6–#8 range. For high-end or instructional work, invest in gas lens setups with glass cups.

Take time to match your cup to your base metal, joint design, and access requirements. That simple swap could mean the difference between a clean pass and a scrapped weld.

WeldSupportParts.com may earn a small commission if you purchase recommended welding products through affiliate links provided on this page—at no additional cost to you.

Leave a Reply