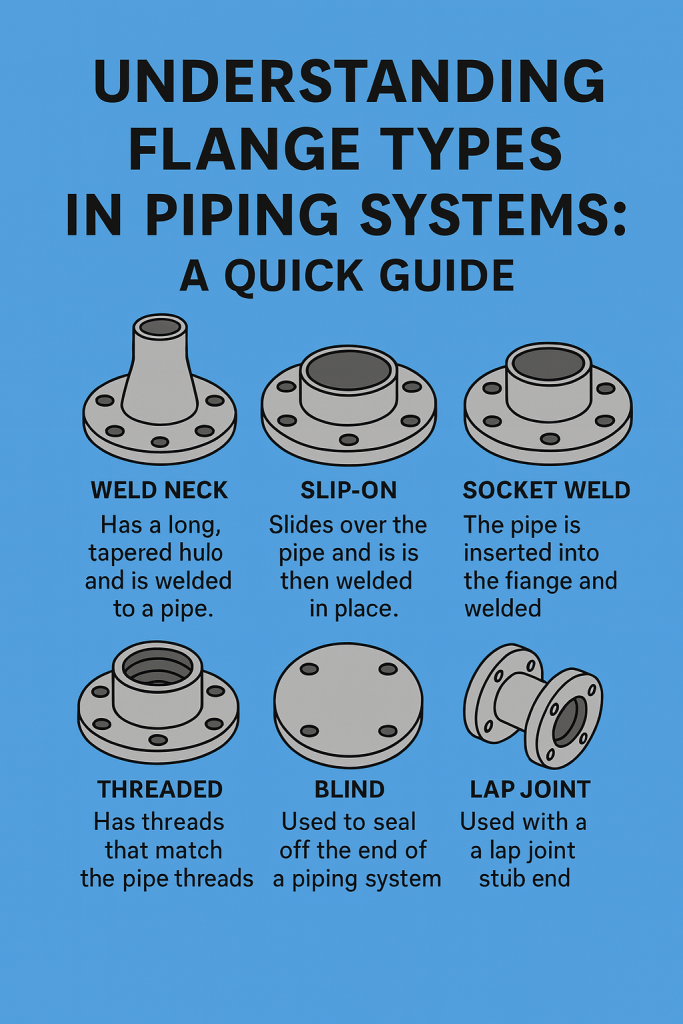

Flanges are essential components in piping systems, used to connect pipes, valves, pumps, and other equipment. They make assembly, disassembly, and maintenance easier and safer. Depending on the application—pressure, temperature, and alignment needs—different flange types are selected. Here’s a breakdown of the most common flange types you’ll encounter in industrial piping.

1. Weld Neck Flange

The weld neck flange features a long, tapered hub that’s welded to the pipe. This design provides excellent stress distribution and mechanical strength, especially in high-pressure and high-temperature applications. It’s the go-to option when structural integrity is critical—common in oil, gas, and power industries.

- Use Case: Refineries, chemical plants

- Strengths: High strength, great for critical systems

- Drawback: Requires skilled welding and is costlier than simpler flanges

2. Slip-On Flange

This flange slides over the pipe and is then fillet welded around both the inside and outside to secure it in place. It’s easier to align and install than weld neck flanges but doesn’t provide the same strength.

- Use Case: Low-pressure water lines or fire protection

- Strengths: Easy to install, cost-effective

- Drawback: Less durable under pressure

3. Socket Weld Flange

With socket weld flanges, the pipe is inserted into a recessed area of the flange and fillet welded on the outside. This flange type offers strong, leak-proof joints for smaller-diameter high-pressure piping systems.

- Use Case: Hydraulic systems, steam lines

- Strengths: Good strength, leak resistance

- Drawback: Limited to smaller sizes and requires welding

4. Threaded Flange

Threaded flanges are screwed onto the pipe rather than welded. This makes them ideal for situations where welding isn’t feasible—like explosive environments or temporary setups.

- Use Case: Fuel lines, low-pressure systems

- Strengths: No welding needed, easy to install

- Drawback: Only suitable for low-pressure, non-critical applications

5. Blind Flange

Blind flanges are solid disks used to close off pipe ends or vessel openings. Since they don’t have a bore, they completely block the flow, making them essential for pressure testing or future pipeline extensions.

- Use Case: Maintenance access points

- Strengths: Strong seal, ideal for pressure testing

- Drawback: High stress under pressure buildup

6. Lap Joint Flange

These are used with a stub end, and the flange itself isn’t welded to the pipe. Instead, it slides over the pipe and is free to rotate, making it easy to align bolt holes. They’re ideal for frequent disassembly and limited space.

- Use Case: Systems requiring regular maintenance or cleaning

- Strengths: Easy to align and disassemble

- Drawback: Less structural strength due to two-part assembly

Other Common Flange Types

While the six types above cover most industrial needs, there are specialty flanges designed for specific purposes.

7. Orifice Flange

These include taps for measuring flow via orifice plates. They are used in systems where precise flow measurement is necessary.

8. Reducing Flange

Used to connect pipes of different diameters without needing a separate reducer fitting. Available in weld neck, slip-on, and threaded forms.

9. Expander Flange

Used to increase pipe size at a connection point. Think of it as the opposite of a reducing flange—handy for expanding system capacity.

10. Specialty Flanges

This category includes proprietary or custom flanges made to ANSI, ASME, or DIN standards for unique or complex installations.

Final Thoughts

Choosing the right flange isn’t just about size—it’s about pressure, temperature, ease of maintenance, cost, and long-term reliability. Weld necks and socket welds are built for strength. Slip-ons and threaded flanges are great for speed and simplicity. Blind and lap joints handle system maintenance and flexibility. Know your application and choose wisely.

Note: This article may contain affiliate links. We may earn a commission if you purchase products through these links, at no extra cost to you.

Leave a Reply