The 11018-M stick welding rod is a low-hydrogen, iron powder-coated electrode used for shielded metal arc welding (SMAW) on high-strength, low-alloy steels. Known for producing strong welds with high impact resistance and excellent mechanical properties, this rod is essential in demanding structural, military, and pressure-vessel applications.

11018-M electrodes are often chosen by professional welders, fabricators, engineers, and QA inspectors working on critical infrastructure, where weld performance and compliance with code standards (such as AWS D1.1 or ASME IX) are non-negotiable.

If you’re welding on quenched and tempered steels or need to meet MIL-spec or code requirements, understanding how to use 11018-M electrodes properly is a must.

Types / Classifications / Variants

While 11018-M is a specific classification under AWS A5.5 for low-alloy steel electrodes, it comes in several variants based on performance and application needs:

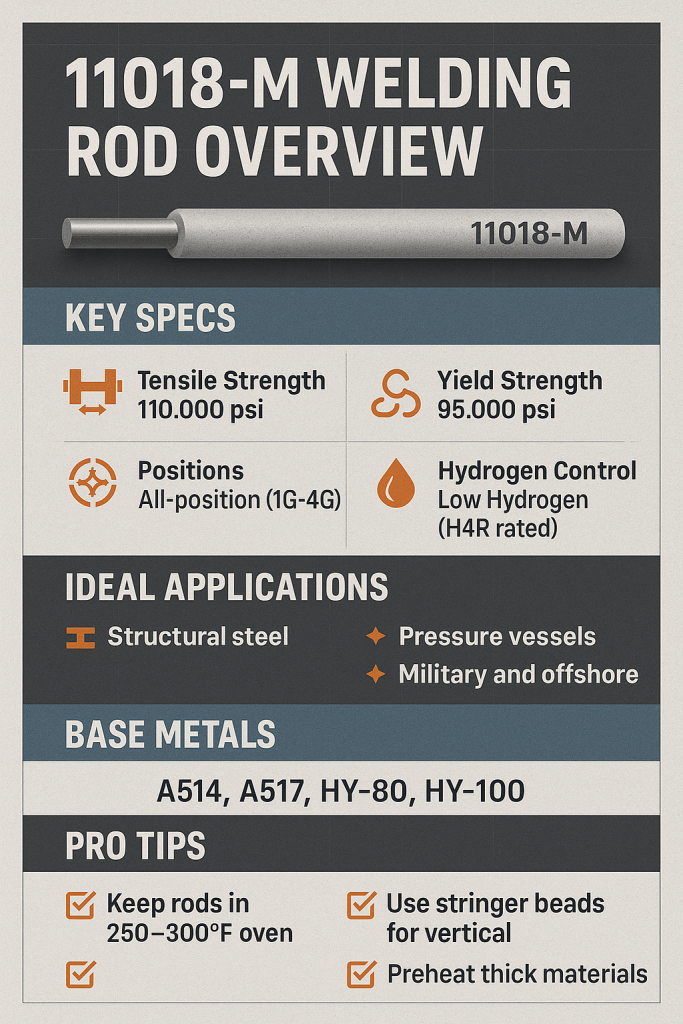

- E11018-M – Standard version with high tensile strength (110 ksi), impact toughness, and low hydrogen content. Designed for structural use and pressure vessels.

- E11018M H4R – Same rod but tested to retain hydrogen levels below 4 mL/100g of weld metal. “R” indicates moisture resistance.

- E11018M-1 – Slightly different chemistry for improved notch toughness at lower temperatures (used in colder environments or offshore applications).

Key AWS Classification Breakdown (E11018-M):

- E = Electrode

- 110 = Minimum tensile strength (110,000 psi)

- 1 = All-position capable

- 8 = Low-hydrogen, iron powder coating

- M = Military grade / CVN impact tested

Key Characteristics or Properties

11018-M rods are designed to deliver high mechanical strength and excellent ductility, even in critical joints subjected to stress, vibration, or extreme temperature shifts.

Technical Specifications:

- Tensile Strength: 110,000 psi (minimum)

- Yield Strength: 95,000 psi (approximate)

- Impact Toughness: ≥20 ft-lb at -50°F (varies by spec)

- Weld Metal Chemistry: Low carbon, alloyed with manganese and nickel

- Coating Type: Low-hydrogen (EXX18), iron powder added for higher deposition

- Positions: All-position (flat, horizontal, vertical up, overhead)

- Amperage Range:

- 1/8″ rod: 100–160 amps (DCEP)

- 5/32″ rod: 140–220 amps (DCEP)

Real-World Example:

If you’re fabricating a crane boom from ASTM A514 steel, 11018-M is often the go-to rod due to its toughness and strength compatibility.

Process Considerations

Welding Process: SMAW (Shielded Metal Arc Welding)

11018-M is SMAW-only, making it ideal for field work and hard-to-reach weldments. It’s often used where wire-fed processes are impractical.

Equipment Compatibility:

- Requires a DCEN/DCEP-capable stick welder (DCEP recommended).

- Best results with a constant current (CC) power source.

- Keep rods in a rod oven at 250–300°F to prevent moisture absorption (low-hydrogen properties depend on this).

Pros:

- High-strength weld metal

- Good impact resistance at low temperatures

- All-position usability

Cons:

- Requires preheat and postheat on some base metals

- Not suitable for thin or low-strength steels

- Rod storage and handling are critical

Application Use Cases

11018-M is designed for critical structural work that requires code compliance and toughness. It’s not for everyday mild steel jobs—this rod shines in specialized applications.

Typical Projects and Industries:

- Bridge and crane fabrication

- Pressure vessels and piping

- Military-grade armor steel

- Offshore platforms

- Power plant infrastructure

- High-strength steel repair welding

Ideal Base Metals:

- ASTM A514 (T1 Steel)

- ASTM A517 (Pressure vessel steels)

- HY-80 and HY-100 naval steels

- MIL-spec structural alloys

What makes this rod unique is that it maintains its strength while resisting cracking under high-stress or low-temperature conditions.

Best Practices & Pro Tips

Proper usage is critical with 11018-M to avoid weld failures. Here are some proven tips:

Rod Handling:

- Store rods in a holding oven (250–300°F) immediately after opening.

- Rebake if exposed to air for more than 4 hours: 650°F for 1–2 hours.

- Don’t skip this—moisture = hydrogen = cracks.

Welding Technique:

- Use short arc length and maintain steady travel speed.

- Avoid weaving on vertical-up stringer beads are preferred.

- The backstep technique can reduce heat buildup on thinner base metal.

Joint Preparation:

- Preheat high-strength steels to 300–400°F to prevent cracking.

- Use post-weld heat treatment (PWHT) if required by the base metal or code.

Safety Tip:

- Due to higher amperage, rods get hotter. Use proper gloves and rod holders to avoid burns when removing stubs.

Conclusion

The 11018-M stick welding rod is a high-performance electrode engineered for critical applications involving high-strength steels. It offers welders the mechanical reliability, toughness, and code compliance needed in structural and pressure-bound environments.

If you’re working on a job that requires CVN-tested welds, high tensile strength, or low hydrogen procedures, this rod belongs in your arsenal. Just make sure you’re handling and storing it properly—this isn’t a rod you treat casually.

Some of the links on this page may be affiliate links. If you purchase through them, we may earn a small commission at no additional cost to you. This helps support our work in providing welding guides and reviews.

- AWS A5.5 E11018M ASME SFA 5.5 E11018M

- 10 LB Package – 11018-M

- 3/32“ Stick Electrode

- Tensile strength (psi) 120,001

- Yield strength (psi) 104,001

- AWS A5.5 E11018M ASME SFA 5.5 E11018M

- 10 LB Package – 11018-M

- 1/8″ Stick Electrode

- Tensile strength (psi) 120,000

- Yield strength (psi) 104,000

- AWS A5.5 E11018M ASME SFA 5.5 E11018M

- 10 LB Package – 11018-M

- 5/32“ Stick Electrode

- Tensile strength (psi) 120,002

- Yield strength (psi) 104,002

Last update on 2026-02-20 / Affiliate links / Images from Amazon Product Advertising API

Leave a Reply