Welding certifications are tightening in 2025. AWS, ANSI, and industry regulators have rolled out updated requirements focused on fatigue prevention, longer-term inflammation risks, exposure limits, and more robust process testing. If you were certified under pre-2025 rules, you may not meet current standards.

Here’s what changed—and what welders, shops, and buyers need to understand right now.

Key Takeaways

- New AWS/ANSI updates increase documentation, safety, and exposure-control requirements

- Older certs may require renewal or supplemental testing

- Emphasis on fatigue prevention, inflammation risk, and fume-exposure management

- Structural, pipe, and automotive codes now reference expanded testing

- Shops should plan for retraining and potential downtime

What Changed for 2025

AWS and ANSI updates don’t overhaul the entire system—but several areas now demand more scrutiny.

1. Fatigue Prevention & Ergonomics (New Focus Area)

For the first time, AWS guidance ties welder conditioning, repetitive-strain exposure, and fatigue management to certification validity within certain shops.

What’s being emphasized:

- Maximum allowable repetition cycles

- Mandatory rest intervals for heavy-position welds

- PPE requirements for vibration and joint stress

- Documentation of overexertion incidents

These aren’t “fitness tests,” but they do affect shop compliance and jobsite audits.

2. Chronic Inflammation & Long-Term Exposure

ANSI Z49.1 references now highlight chronic inflammation risks from:

- Metal fume inhalation

- Heavy particulate exposure

- Long-duration heat/UV exposure

Shops are expected to update:

- Fume extraction plans

- Airflow documentation

- Respiratory PPE fit-testing logs

- Heat-stress protocols

This ties directly into certification renewals for certain industries.

3. Tighter Process Testing for Certification

Across AWS D1.1 (structural), D1.3 (sheet steel), D17.1 (aerospace), and B31 pipe codes, many certs now require:

- More detailed weld-procedure records

- Updated documentation of parameters

- Expanded visual exam criteria

- New acceptance limits for cumulative defects

Pre-2025 certifications may require requalification or supplemental weld tests.

Old vs. New (Quick Breakdown)

| Area | Pre-2025 Standard | 2025 Standard |

|---|---|---|

| Fatigue Prevention | Minimal mention | Mandatory documentation + rest cycle guidelines |

| Chronic Inflammation Risk | General fume guidance | Expanded exposure limits + detailed PPE compliance |

| Fume Extraction | Recommended | Required in most shop audits |

| Cert Validity Windows | Standard intervals | Some industries shortened validity periods |

| Process Testing | Visual + bend tests | Tighter acceptance criteria and expanded documentation |

| Medical Risk Notes | Rarely included | Now referenced in several AWS/ANSI publications |

Which Certifications Matter Most in 2025

Different industries now lean heavily on updated standards. Here’s what welders and shops need to prioritize.

Structural (AWS D1.1)

Expect:

- Stricter visual standards

- Additional position testing for some shops

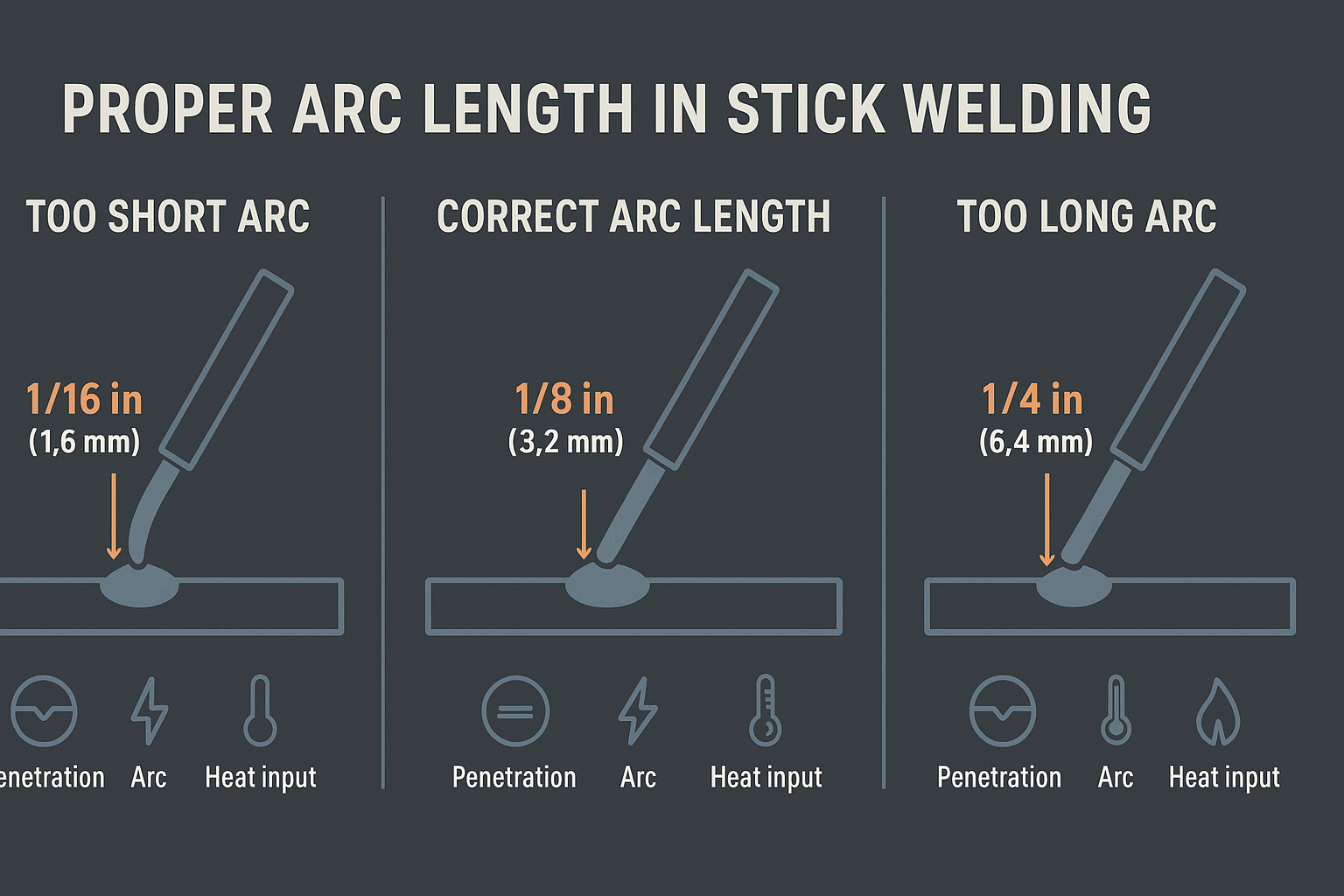

- More documentation on parameters and heat input

Pipe Welding (ASME / B31 Series)

Tighter tolerance for:

- Root reinforcement

- Internal misalignment

- Heat-affected zone integrity

Automotive / Manufacturing (AWS D8/D9)

New focus on:

- Repetitive-strain prevention

- Heat-stress logs

- Exposure management for high-volume weld cells

Aerospace (AWS D17.1)

More stringent:

- Visual inspection criteria

- Traceability requirements

- Operator-specific parameter logs

Why It Matters for Welders

1. Certifications from 2024 may not satisfy 2025 audit requirements

Many shops will require updated test plates or documentation.

2. Retraining budgets matter now

Expect more formal training, especially around exposure prevention.

3. Higher certification standards = higher labor rates

Buyers should expect increased cost per hour for certified welders, especially in pipe, structural, and aerospace.

Where to Buy Safety Upgrades

With stricter exposure-control and fatigue-management rules, PPE and ventilation gear matter more than ever.

ArcWeld Store PPE Essentials:

www.arcweld.store

Safety Notes (AWS/ANSI References)

- Follow ANSI Z49.1 for exposure and fume-control guidelines

- Ensure fit testing for respirators per OSHA 1910.134

- Use NIOSH-approved PPE for metals containing Cr, Ni, Mn, or aluminum

- Maintain proper airflow and extraction in accordance with AWS safety recommendations

FAQ

Do I need to retake my welding test in 2025?

Possibly—especially for structural, pipe, and aerospace work. Many shops require updated certs.

What if my employer still uses old standards?

They may fail audits or be unable to bid certain jobs.

Do these rules affect hobby welders?

No, these updates primarily affect commercial shops and certified welders.

How often should I renew my certification now?

Depends on code. Some industries shortened validity windows under 2025 guidance.