Carbon arc gouging and plasma gouging both remove metal fast—but they serve different jobs, budgets, and shop environments. This guide breaks down how each process works, when to use one over the other, and what to expect for performance, cost, and safety.

Key Takeaways

- Carbon arc gouging is cheaper to operate and works anywhere you have adequate air and amperage.

- Plasma gouging (Hypertherm) delivers cleaner, more precise results with less post-grinding.

- Plasma gouging has higher equipment cost but faster learning curve and less mess.

- Carbon arc is loud, dirty, and requires high current; plasma is cleaner but more expensive to maintain.

- For production shops and precision repair work, plasma wins. For heavy removal at lowest cost, carbon arc is still king.

Where to Buy

Arc Weld Store – Recommended:

Carbon arc torches, gouging carbons, and air systems:

https://www.arcweld.store/collections/esab-carbon-arc-slice-torch

How Each Process Works

Carbon Arc Gouging (CAC-A)

Carbon arc gouging uses a graphite/carbon electrode to melt the base metal with high amperage while compressed air blows the molten metal away.

Typical Specs (Manufacturer Ranges, AWS C5.3):

- Current: 300–1200 A depending on electrode size

- Voltage: 35–55 V

- Air Pressure: ~80–100 psi

- Air Flow: ~20 cfm minimum

- Electrode Types: DC+, copper-coated carbons

- Noise: 110–125 dB (hearing protection required)

Strengths

- Lowest equipment cost

- Removes large volumes of metal quickly

- Works indoors/outdoors, even in dirty field conditions

- Repair shops & fab shops already wired for high amps

Weak Points

- Extremely loud

- Heavy spatter and carbon dust

- Large heat-affected zone

- More grinding required after gouging

Hypertherm Plasma Gouging

Plasma gouging uses a constricted plasma arc to heat and remove metal with very controlled airflow. Hypertherm systems (Powermax series) are the industry standard.

Typical Specs (Hypertherm Powermax):

- Output: 45–125 A depending on system

- Gouge Depth: Light to medium removal

- Air Pressure: ~90–120 psi (per model spec sheet)

- Duty Cycle: Model-dependent; most 60–100% at rated output

- Noise: Lower than carbon arc; still requires hearing protection

Strengths

- Very controlled and predictable gouge

- Reduced post-grinding

- Less carbon contamination

- Quieter and cleaner than CAC-A

- Works extremely well on stainless and aluminum

Weak Points

- Higher equipment cost

- Consumables are more expensive

- Not ideal for deep, aggressive removal

- Requires dry, clean air supply

Which One Should You Use?

If you need maximum metal removal at lowest cost → Choose Carbon Arc Gouging

Great for:

- Heavy plate bevels

- Removing welds on thick structural steel

- Field repair

- Shops already running 600–1000 A power sources

If you need cleaner, controlled gouges with minimal cleanup → Choose Hypertherm Plasma Gouging

Great for:

- Stainless & aluminum work

- Pressure vessel repairs

- Precision removal (cracks, isolated welds)

- Indoor fabrication environments

- Operators needing fast training curve

Comparison Table

| Model/Process | Key Specs | Best For |

|---|---|---|

| CAC-A Carbon Arc Torch (Generic Industrial) | 300–1200 A, 80–100 psi | Heavy gouging, lowest cost |

| Hypertherm Powermax 65/85 Gouging | 65–85 A plasma gouging, precise removal | Clean, controlled gouging |

Practical Considerations & Setup

Air System Requirements

Both processes require dry, steady airflow. Plasma is more sensitive—wet air destroys consumables.

- Install a dryer or desiccant if plasma gouging.

- Carbon arc tolerates “shop air” but still benefits from dryness.

Power Requirements

- Carbon arc requires sizable 3-phase machines or engine drives.

- Plasma gouging can run on standard Hypertherm Powermax units (45–125 A).

Skill Level

- Carbon arc demands better hand control to avoid digging.

- Plasma gouging is easier to learn; the arc is more stable and directional.

Safety Notes

- Use ANSI Z87.1-rated eye protection (shade per AWS F2.2 recommendations—typically shade 10–12 for CAC-A, 8–10 for plasma).

- Wear full PPE, flame-resistant clothing, and hearing protection (both processes exceed 100 dB).

- Ensure adequate ventilation; carbon arc creates carbon dust and fumes.

- Follow manufacturer guidelines for electrode size, air pressure, and duty cycle (Hypertherm, AWS C5.3 for CAC-A).

FAQ

Is plasma gouging as fast as carbon arc gouging?

No. Plasma is cleaner and more controlled, but CAC-A removes metal significantly faster.

Is carbon arc gouging bad for stainless?

It can leave carbon contamination. Plasma is preferred for stainless/aluminum.

Can you gouge outdoors with plasma?

Yes, but wind can disrupt arc stability more than CAC-A.

Does Hypertherm sell dedicated gouging consumables?

Yes—consult the Hypertherm Powermax series gouging nozzle and shield charts.

Sources Checked

- Hypertherm Powermax 45/65/85/105 Spec Sheets

- AWS C5.3: Recommended Practices for Air Carbon Arc Cutting and Gouging

- Manufacturer data for carbon electrodes and torches

Where to Buy

Arc Weld Store:

https://www.arcweld.store/collections/esab-carbon-arc-slice-torch

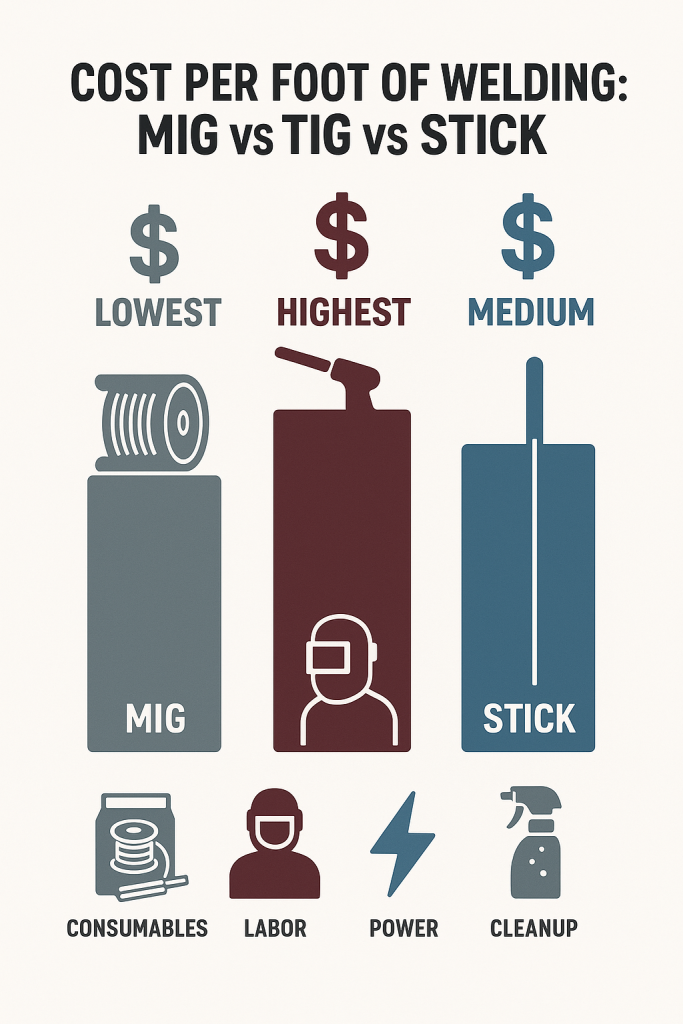

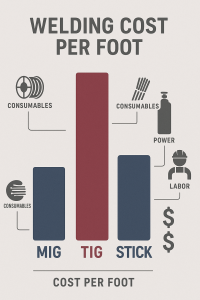

MIG Welding (GMAW) – High Speed, Low Cost

MIG Welding (GMAW) – High Speed, Low Cost

Assumptions:

Assumptions: MIG Welding Cost Example

MIG Welding Cost Example $0.89/ft

$0.89/ft