Welding safety glasses protect against UV radiation, infrared light, and impact hazards during grinding and fabrication. Choosing the right glasses depends on process type, shade number, and ANSI Z87.1 certification—not just lens color.

ANSI Z87.1 Certification Requirements

Impact Protection Levels

Basic Impact (Z87) – Protects against low-velocity impact (1” steel ball at 150 ft/sec) – Suitable for: General shop work, light grinding, non-welding tasks

High Impact (Z87+) – Protects against high-velocity impact (1/4” steel ball at 150 ft/sec) – Required for: Welding, grinding, chipping, cutting – Marking: “Z87+” stamped on frame and lens

Side Shield Requirement: – All welding safety glasses must have side shields or wraparound design – Prevents spatter and debris from entering around lens edges

Shade Number Selection by Process

| Process | Amperage Range | Shade Number | Lens Type |

|---|---|---|---|

| Oxy-fuel cutting | N/A | #3-#6 | Fixed shade |

| TIG (GTAW) | 10-50A | #8-#10 | Fixed or auto-darkening |

| TIG (GTAW) | 50-150A | #10-#12 | Fixed or auto-darkening |

| MIG (GMAW) | 60-160A | #10-#12 | Fixed or auto-darkening |

| MIG (GMAW) | 160-250A | #12-#14 | Fixed or auto-darkening |

| Stick (SMAW) | 60-160A | #10-#12 | Fixed shade |

| Stick (SMAW) | 160-250A | #12-#14 | Fixed shade |

| Plasma cutting | 20-40A | #4-#5 | Fixed shade |

| Plasma cutting | 40-80A | #5-#8 | Fixed shade |

Note: Safety glasses are supplemental protection worn under welding helmets or for indirect arc exposure (helper/observer).

Lens Types & Technologies

Fixed Shade Lenses

- Pros: No batteries, consistent darkness, low cost

- Cons: Single shade only, must swap lenses for different processes

- Best for: Dedicated single-process work, backup glasses

- Cost: $10-$30

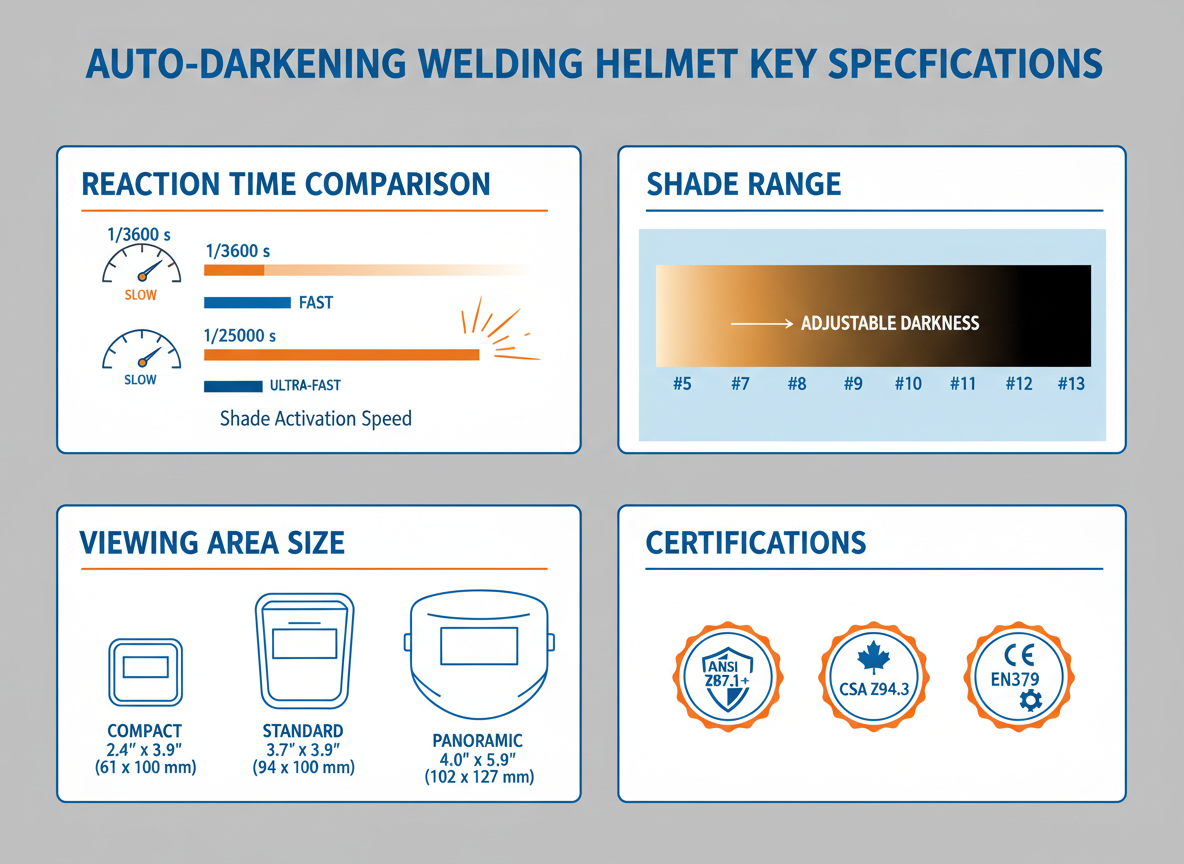

Auto-Darkening Lenses

- Pros: Adjustable shade range, no lens swapping

- Cons: Battery replacement, higher cost

- Shade range: Typically #5-#13

- Reaction time: 0.0001-0.00004 seconds

- Best for: Multi-process shops, frequent shade changes

- Cost: $50-$150

Passive IR/UV Protection (Clear Lenses)

- Function: Blocks UV and infrared without visible light darkening

- Use case: Grinding, fabrication, indirect arc exposure (helper/observer)

- Shade equivalent: #1.5-#2

- Best for: Non-welding tasks requiring impact protection

UV & IR Protection Standards

UV Protection (200-400nm wavelength): – All welding lenses must block 99.9%+ UV radiation – Permanent damage occurs from unprotected UV exposure (arc eye/welder’s flash)

Infrared Protection (780nm-1mm wavelength): – Blocks heat radiation from welding arc – Prevents retinal damage and cataracts from prolonged exposure

Visible Light Transmission: – Shade #3: 14.3% transmission (light tint) – Shade #8: 0.58% transmission (moderate darkness) – Shade #12: 0.0018% transmission (very dark)

Lens Coatings & Features

Anti-Fog Coating

- Purpose: Prevents condensation in humid environments or when wearing respirator

- Best for: Summer welding, enclosed spaces, respirator use

- Limitation: Coating wears off after 6-12 months

Anti-Scratch Coating

- Purpose: Extends lens life in high-abrasion environments

- Best for: Grinding, fabrication, production shops

- Hardness rating: 4-6H pencil hardness (military spec MIL-PRF-32432)

Polarized Lenses

- Purpose: Reduces glare from reflective surfaces (polished stainless, aluminum)

- Best for: TIG welding on reflective materials

- Limitation: Not necessary for carbon steel or general fabrication

Frame Styles & Fit

Wraparound Design

- Coverage: Maximum side and peripheral protection

- Best for: Grinding, cutting, high-spatter welding

- Fit: Snug to face, minimal gap around edges

Over-the-Glass (OTG) Design

- Purpose: Fits over prescription eyeglasses

- Best for: Welders who wear corrective lenses

- Limitation: Bulkier, may not fit all prescription frame sizes

Prescription Welding Glasses

- Purpose: Combines corrective lenses with welding shade

- Best for: Full-time welders who need vision correction

- Cost: $150-$400 (requires optometrist fitting)

When to Wear Safety Glasses vs. Helmet

Safety Glasses (Supplemental Protection)

- Grinding, cutting, or fabrication (no arc)

- Indirect arc exposure (helper/observer 10+ feet from arc)

- Under welding helmet as secondary protection

- Oxy-fuel cutting or brazing (low UV output)

Welding Helmet (Primary Protection)

- Direct arc exposure (TIG, MIG, stick, flux-core)

- Primary welder performing arc welding

- Required for all arc welding processes per OSHA 1910.252

OSHA Requirement: Safety glasses must be worn under welding helmets in environments with grinding, chipping, or multiple welding stations.

Common Mistakes

Using non-certified safety glasses for welding

Fashion sunglasses or non-Z87+ glasses don’t block UV/IR radiation. Result: arc eye (photokeratitis) and permanent retinal damage. Always verify Z87+ marking.

Wrong shade number for amperage

Shade #3 glasses for 150A MIG = retinal burn risk. Shade #12 for oxy-fuel cutting = can’t see work. Match shade to process and amperage.

Skipping safety glasses under helmet

Grinding debris or spatter can enter under helmet. OSHA requires safety glasses as secondary protection in multi-hazard environments.

Buying Checklist

- ✓ ANSI Z87+ certification marked on frame and lens

- ✓ Shade number matches process and amperage range

- ✓ UV/IR protection rated for welding (99.9%+ UV block)

- ✓ Side shields or wraparound design for peripheral protection

- ✓ Anti-fog coating if working in humid environments

- ✓ Anti-scratch coating for grinding/fabrication work

- ✓ Comfortable fit (no pressure points, secure without slipping)

- ✓ OTG design if wearing prescription glasses