MIG wire selection affects weld quality, spatter levels, and penetration depth. Choosing the right wire depends on base metal composition, surface condition, and shielding gas—not just diameter and tensile strength.

Common MIG Wire Classifications

ER70S-6 (Most Common)

- Deoxidizers: Manganese, silicon

- Tensile strength: 70,000 PSI minimum

- Best for: Dirty or rusty steel, single-pass welds, general fabrication

- Shielding gas: 75/25 Ar/CO₂ or 100% CO₂

- Spatter level: Moderate

ER70S-3

- Deoxidizers: Lower manganese and silicon than ER70S-6

- Tensile strength: 70,000 PSI minimum

- Best for: Clean steel, multi-pass welds, automotive sheet metal

- Shielding gas: 75/25 Ar/CO₂ (100% CO₂ not recommended)

- Spatter level: Low

ER308L (Stainless Steel)

- Composition: 19-21% chromium, 9-11% nickel

- Best for: 304/304L stainless steel

- Shielding gas: 90/10 Ar/CO₂ or tri-mix (He/Ar/CO₂)

- Corrosion resistance: Excellent

ER316L (Stainless Steel)

- Composition: 18-20% chromium, 11-14% nickel, 2-3% molybdenum

- Best for: 316/316L stainless, marine environments, chemical processing

- Shielding gas: 90/10 Ar/CO₂ or tri-mix

- Corrosion resistance: Superior (molybdenum addition)

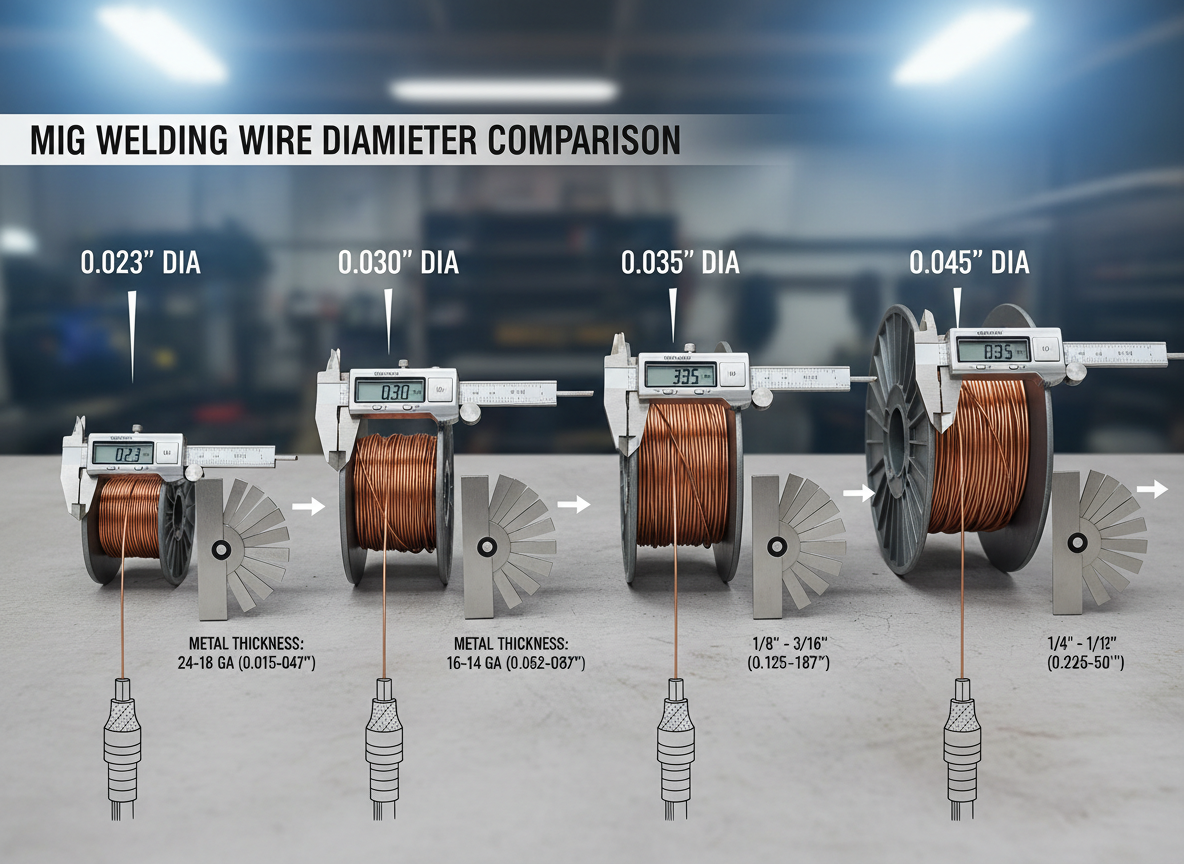

Wire Diameter Selection

| Diameter | Amperage Range | Material Thickness | Typical Use |

|---|---|---|---|

| 0.023” | 30-130A | 24-18 gauge | Automotive sheet metal, thin tubing |

| 0.030” | 40-145A | 18-14 gauge | General fabrication, light structural |

| 0.035” | 50-180A | 14 gauge-1/4” | Most common all-purpose size |

| 0.045” | 75-250A | 1/4”-1/2” | Heavy structural, thick plate |

| 0.052” | 100-300A | 1/2”+ | Industrial fabrication, heavy equipment |

Rule of thumb: Thinner wire = better control on thin material. Thicker wire = faster deposition on heavy plate.

Shielding Gas Impact on Wire Performance

75/25 Argon/CO₂ (C25)

- Pros: Low spatter, smooth arc, good bead appearance

- Cons: Higher cost than 100% CO₂

- Best for: ER70S-3, ER70S-6, stainless steel

100% CO₂

- Pros: Deep penetration, low cost

- Cons: Higher spatter, rougher arc

- Best for: ER70S-6 on thick steel (not recommended for ER70S-3)

90/10 Argon/CO₂

- Pros: Minimal spatter, excellent for stainless

- Cons: Shallow penetration on carbon steel

- Best for: ER308L, ER316L stainless wire

Surface Condition Requirements

| Wire Type | Mill Scale | Light Rust | Heavy Rust | Clean Steel |

|---|---|---|---|---|

| ER70S-6 | ✓ | ✓ | ✓ | ✓ |

| ER70S-3 | ✗ | ✗ | ✗ | ✓ |

| ER308L | ✗ | ✗ | ✗ | ✓ |

| ER316L | ✗ | ✗ | ✗ | ✓ |

ER70S-6 advantage: Higher deoxidizers clean impurities during welding. ER70S-3 requires clean base metal to avoid porosity.

AWS Filler Metal Specifications

AWS A5.18 (Carbon Steel MIG Wire) – Covers ER70S-3, ER70S-6, and other carbon steel wires – Defines chemical composition, tensile strength, and elongation requirements

AWS A5.9 (Stainless Steel MIG Wire) – Covers ER308L, ER316L, and other stainless wires – Specifies corrosion resistance and ferrite content

Wire Storage & Handling

Moisture Contamination – Causes: Porosity, hydrogen cracking – Prevention: Store in sealed containers with desiccant packs – Shelf life: 12 months (carbon steel), 6 months (stainless)

Wire Feed Issues – Kinked wire = erratic arc and bird-nesting – Solution: Use proper spool tension and liner size

Liner Compatibility

| Wire Diameter | Liner Inside Diameter |

|---|---|

| 0.023”-0.030” | 0.030”-0.035” |

| 0.035” | 0.035”-0.045” |

| 0.045” | 0.045”-0.052” |

| 0.052” | 0.052”-0.062” |

Oversized liner = wire wander. Undersized liner = excessive friction and burnback.

Common Mistakes

Using ER70S-3 on rusty steel

Low deoxidizers can’t compensate for surface contamination. Result: porosity and weak welds. Use ER70S-6 or clean the base metal.

Wrong liner size for wire diameter

0.035” wire in 0.045” liner causes erratic feeding. Match liner to wire diameter within 0.005”-0.010”.

Storing stainless wire without moisture protection

Stainless wire absorbs moisture faster than carbon steel. Always use sealed containers with desiccant.

Buying Checklist

- ✓ Wire classification matches base metal (ER70S-6 for dirty steel, ER70S-3 for clean)

- ✓ Diameter suits material thickness and amperage range

- ✓ Shielding gas compatible with wire type

- ✓ AWS A5.18 or A5.9 certification marked on spool

- ✓ Liner size matches wire diameter

- ✓ Storage container includes moisture protection

- ✓ Spool size fits your machine (2 lb, 10 lb, 33 lb, 44 lb)

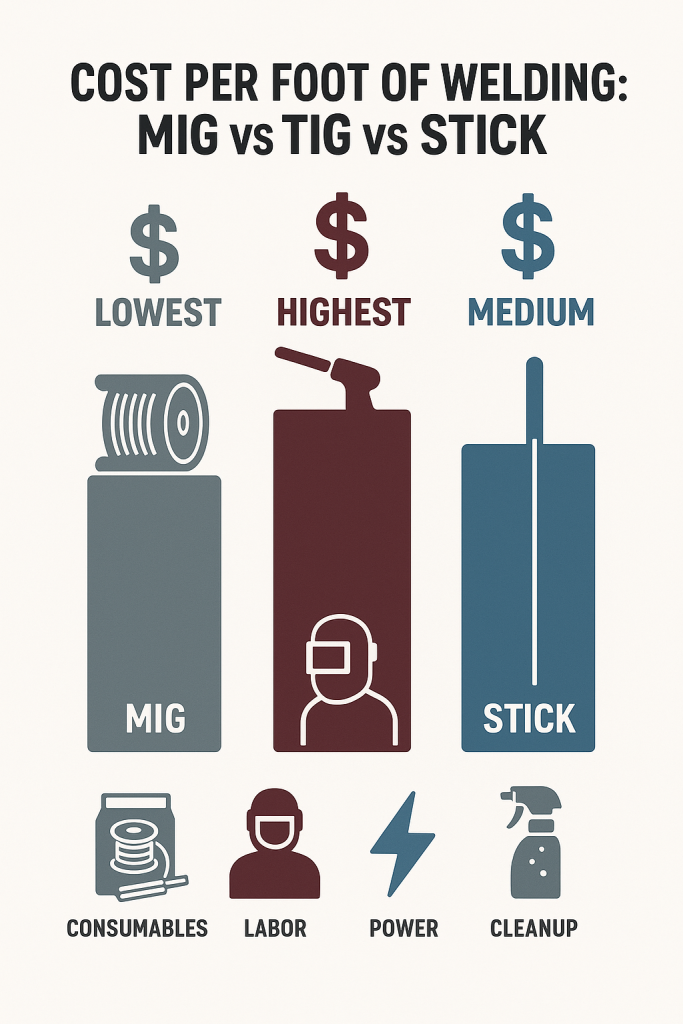

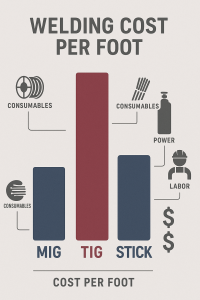

MIG Welding (GMAW) – High Speed, Low Cost

MIG Welding (GMAW) – High Speed, Low Cost

Assumptions:

Assumptions: MIG Welding Cost Example

MIG Welding Cost Example $0.89/ft

$0.89/ft