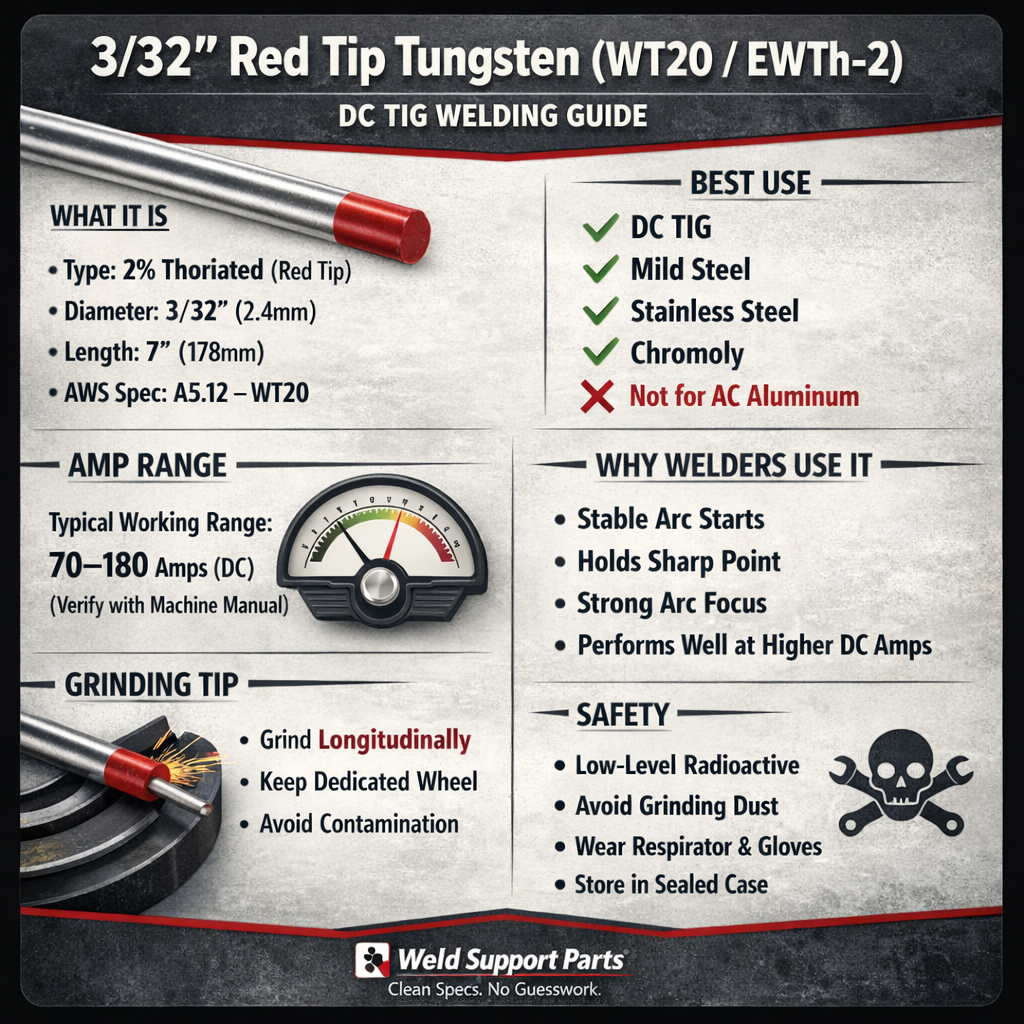

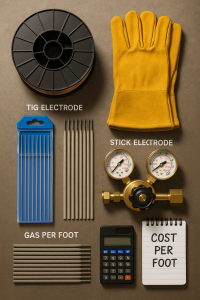

Selecting the correct tungsten electrode directly affects arc stability, weld appearance, and electrode life. 3/32″ 2% thoriated (WT20/EWTh-2) is a long-time standard for DC TIG welding on steel and stainless. Here’s what matters before you buy.

Key Takeaways

- 3/32″ (2.4mm) fits most 70–180A DC TIG applications

- Red tip (2% thoriated) offers stable arc starts and strong arc focus

- Best for DC welding on steel and stainless

- Not recommended for AC aluminum

- Grind longitudinally to maintain arc control

Where to Buy

- RED TIP: The red band tungsten electrode is a traditional outstanding welding electrode, whose arc is continuous, stable, without spreading and dispersing. As it is not easy to get a round top with thermostability, it performs well in a lifetime.

- AWS CERTIFIED: AMERICAN Welding Society standard AWS A5.12M/A5.12:2009 conformance

- UPGRADED PACKAGING: We’ve upgraded from a plastic case to a high-strength, sealed aluminum tube. This airtight design prevents electrode oxidation, ensuring stable arc performance and perfect welds. The innovative dual-open design offers easy access to all electrode lengths, while the rugged, compact build is drop-resistant and portable—ready for your pocket, toolbox, or belt loop

- PERFECT DESIGN: By checking the color of the outer packaging, you can quickly and easily distinguish the color and model of tungsten electrodes, saving your time and reducing the possibility of errors

- SPECIFICATION: Diameter: 3/32″; Length: 7″; Quantity: 10pk

Last update on 2026-03-07 / Affiliate links / Images from Amazon Product Advertising API

Disclosure: As an Amazon Associate, Weld Support Parts earns from qualifying purchases.

Why 3/32″ WT20 Is Popular

Arc Stability

Thoriated tungsten maintains a sharp point under DC current, producing a focused arc and clean starts.

Amp Range

Typical usable range: 70–180A DC (verify with machine manual).

Works well for:

- Mild steel

- Stainless steel

- Chromoly

- Field repair work

Grind Matters

Always grind lengthwise (not around the circumference).

Use a dedicated tungsten grinder or clean wheel to prevent contamination.

Specs

| Spec | Value |

|---|---|

| Diameter | 3/32″ (2.4mm) |

| Length | 7″ (178mm) |

| Classification | WT20 / EWTh-2 |

| Composition | 2% Thoriated |

| Process | DC TIG |

| AC Aluminum | Not recommended |

Who Should Use This

Best for:

- DC TIG welders running steel or stainless

- Shop and field repair

- Welding instructors

Skip if:

- You weld mostly aluminum (use lanthanated or pure)

- You prefer non-radioactive options (choose ceriated or lanthanated)

Safety

- Thoriated tungsten contains low-level radioactive material

- Avoid inhaling grinding dust

- Wear respirator and gloves when sharpening

- Follow AWS A5.12 classification guidance

FAQ

Can I use red tip tungsten on aluminum?

No. It’s designed for DC welding.

Is thoriated tungsten radioactive?

Yes, at low levels. Safe in use but avoid dust inhalation.

What’s the advantage over ceriated?

Better performance at higher DC amperage.

How often should I regrind?

When arc stability decreases or contamination occurs.

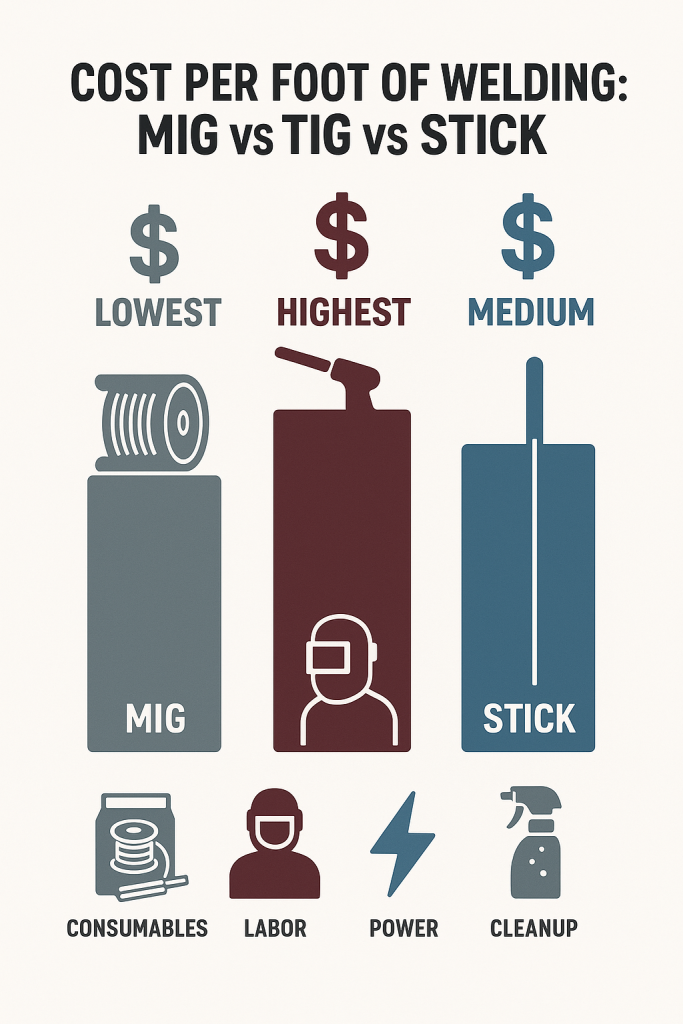

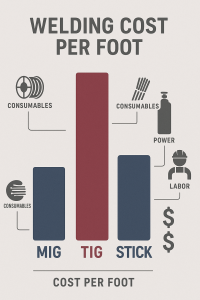

MIG Welding (GMAW) – High Speed, Low Cost

MIG Welding (GMAW) – High Speed, Low Cost

Assumptions:

Assumptions: MIG Welding Cost Example

MIG Welding Cost Example $0.89/ft

$0.89/ft