Introduction

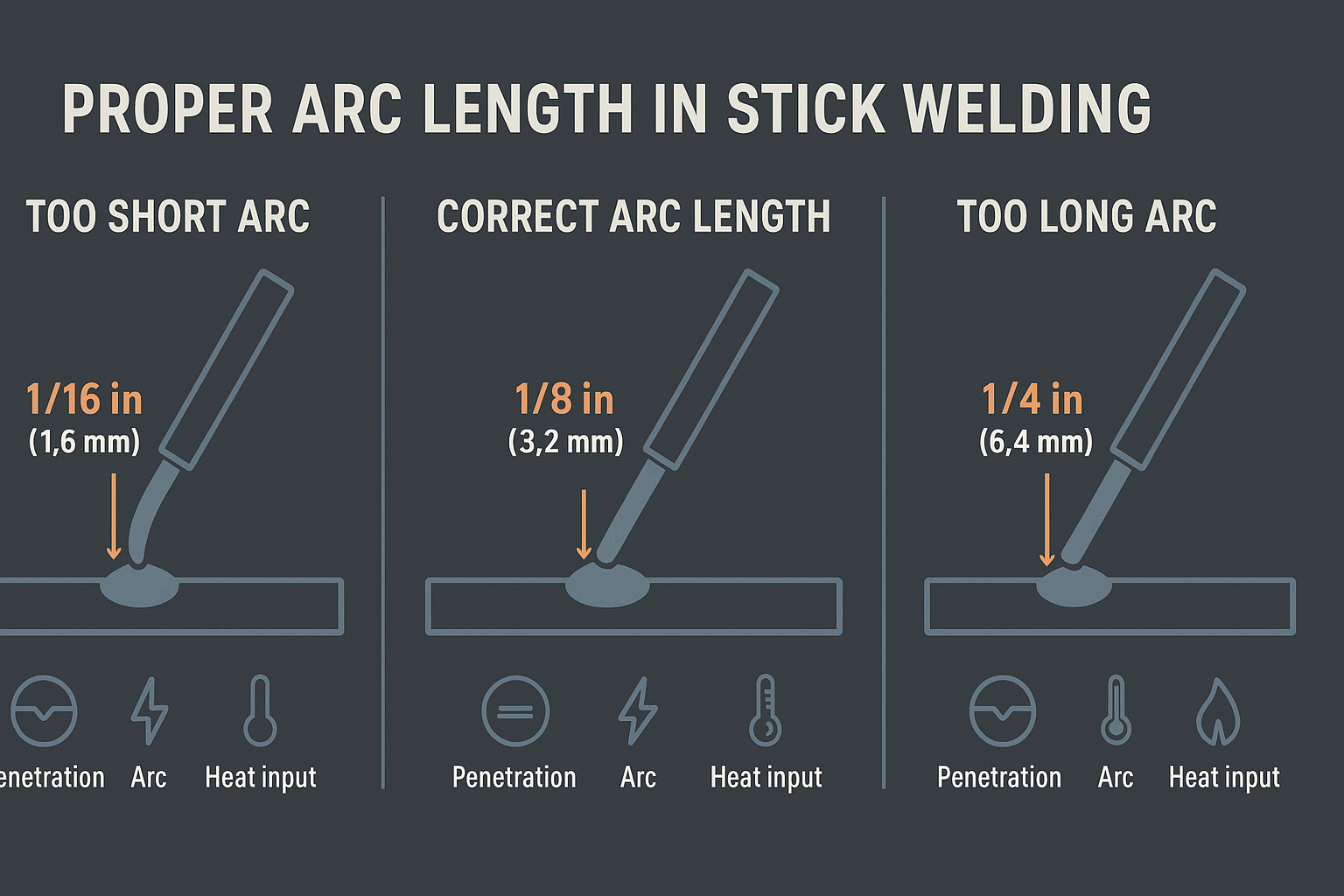

Arc length is one of the most important variables in stick welding, and this guide—Arc Control: Why Arc Length Matters in Stick Welding—breaks down exactly why. The book explains how arc length influences penetration, bead shape, stability, and overall weld quality. For new welders trying to stop sticking and wandering arcs, and for experienced welders chasing cleaner, more consistent beads, this resource provides straightforward direction.

Key Features

This guide focuses entirely on understanding and maintaining proper arc length. Core topics include:

- How arc length affects heat input and penetration

- How arc stability changes with electrode angle and travel speed

- The relationship between arc length, puddle control, and weld bead behavior

- Visual diagrams that show what “too long” and “too short” arcs look like

- Simple, actionable tips welders can use immediately

It’s written in plain language with enough detail to be useful without overwhelming beginners.

Pros & Cons

Pros

- Clear explanations of how arc length affects weld quality

- Applicable to all experience levels

- Helpful illustrations and diagrams

- Strong focus on practical, real-world improvement

Cons

- Doesn’t include advanced technical data

- Could go deeper for welders who already have strong arc control

Who It’s For

This guide fits welders who want more consistency and better quality out of their SMAW work. Ideal groups include:

- Welding students learning fundamentals

- DIY welders trying to reduce sticking and uneven beads

- Working welders who want tighter control and repeatable results

- Anyone who struggles with keeping a steady arc length

What Makes It Unique

Most welding books touch on arc length but don’t spend much time on it. This guide focuses specifically on that variable and explains it step-by-step. The visuals help welders understand what they should see, and the practical advice makes it easy to apply on the next weld.

Buying Tips

For the best learning experience:

- Look for editions that include diagrams, photos, or companion videos

- Choose the latest version if updates are available

- Make sure you have basic PPE and electrodes on hand so you can practice

- Pair the guide with a machine that has stable output—helpful when learning arc control

Conclusion

Arc Control: Why Arc Length Matters in Stick Welding is a solid resource for anyone wanting stronger, cleaner, and more consistent stick welds. It breaks down arc length in a way that welders can understand and apply immediately. Beginners and seasoned welders alike will find something useful here.

This article may contain Amazon affiliate links. We may earn a small commission at no extra cost to you.

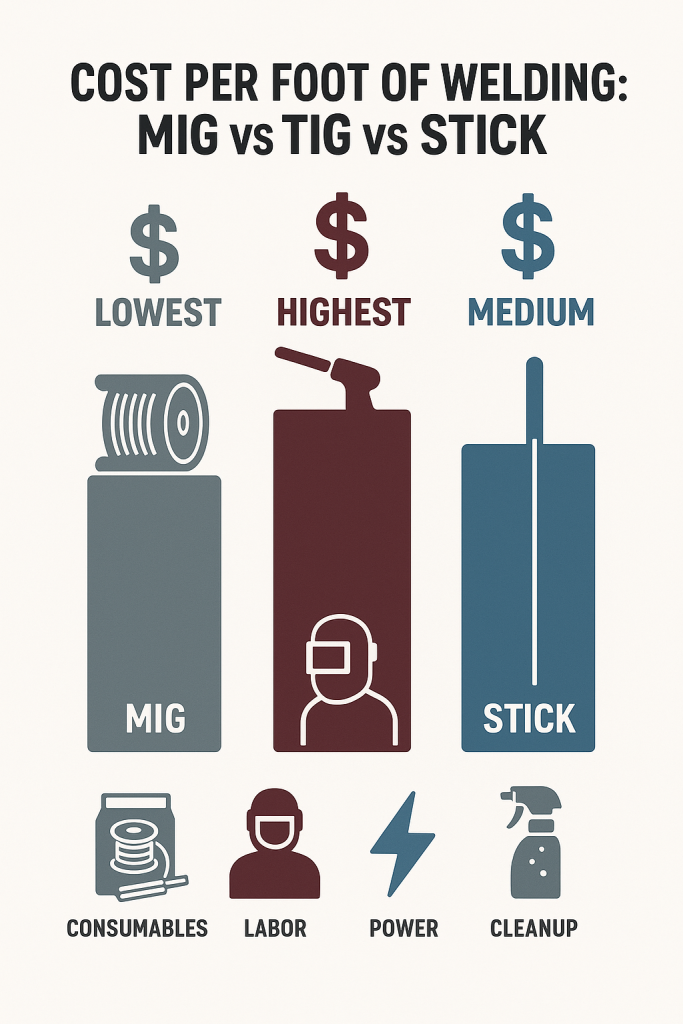

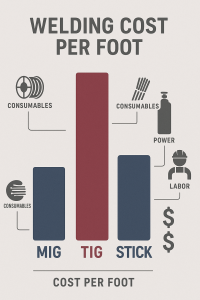

MIG Welding (GMAW) – High Speed, Low Cost

MIG Welding (GMAW) – High Speed, Low Cost

Assumptions:

Assumptions: MIG Welding Cost Example

MIG Welding Cost Example $0.89/ft

$0.89/ft