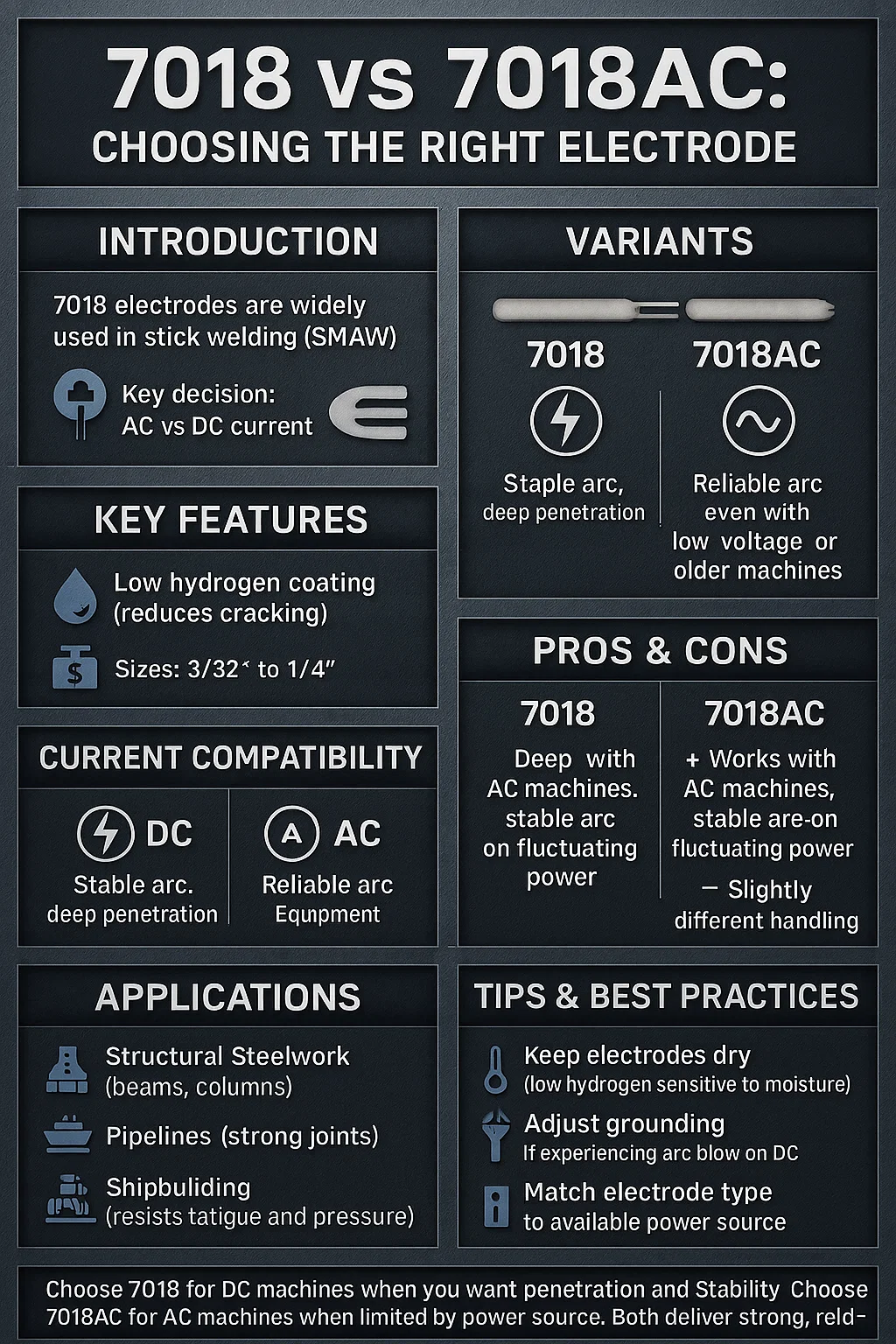

Introduction

Welding with 7018 electrodes is a staple in shielded metal arc welding (SMAW), also known as stick welding. Known for creating strong, smooth welds, the 7018 is frequently used in critical applications such as structural steel work. A common question among welders is whether to use AC or DC current with this electrode, and when to opt for the 7018AC variant. Understanding these choices is crucial for welders, fabricators, and students striving for optimal performance.

Types / Variants / Models

The primary variants include:

- 7018 Electrode: Typically used with direct current electrode positive (DCEP).

- 7018AC Electrode: Specifically designed for alternating current (AC) applications.

Each variant excels under different conditions, making the choice between them vital depending on the available equipment and project requirements.

Key Features or Specifications

- Coating Composition: Low hydrogen, iron powder which minimizes the risk of cracking.

- Current Type:

- 7018: Best with DCEP for stability and penetration.

- 7018AC: Optimized for AC, offering good arc stability even with lower voltage machines.

- Sizes: Available from 3/32″ to 1/4″, depending on thickness needs.

- Certifications: Meets AWS A5.1 standards ensuring quality and reliability across structural applications.

The differences in current compatibility directly affect arc stability and penetration, essential for achieving robust, high-quality welds.

Usage & Compatibility

Welding Processes:

- SMAW (Stick Welding): The preferred method for 7018, ensuring strength in welds.

Machine Compatibility:

- DC Machines: Offer stable arcs with deeper penetration for the standard 7018.

- AC Machines: Enable the use of 7018AC, overcoming limitations of older or less robust machines prone to arc interruptions.

Pros and Cons:

- 7018 with DC:

- Pros: Deeper penetration, better arc stability.

- Cons: Requires DC-compatible equipment.

- 7018AC:

- Pros: Usable with AC machines, improved arc stability on fluctuating AC power.

- Cons: Slightly different handling required due to AC characteristics.

Common Applications

Welding with 7018 electrodes is prevalent in:

- Structural Steelwork: Essential for beams and columns due to its strength.

- Pipeline Welding: Ensures solid joints crucial for durability.

- Shipbuilding: Vital in combating metal fatigue and environmental pressures.

The 7018AC variant is particularly useful in field repairs and projects where only AC power sources are available, providing necessary flexibility and reliability.

Tips & Best Practices

- Setup: For AC use, ensure a stable power supply to reduce fluctuations.

- Handling: Maintain dry storage for electrodes to prevent moisture absorption, particularly for low-hydrogen types.

- Troubleshooting: If experiencing arc blow on DC, try adjusting the grounding position or switch to 7018AC for better control.

Avoid common mistakes such as incorrect polarity settings and improper storage, which can compromise weld quality.

Conclusion

Choosing between AC and DC currents for 7018 electrodes hinges on equipment availability and project needs. The 7018AC variant provides a viable option for those restricted to AC machines without sacrificing weld quality. Welders and students should assess their equipment and project requirements to make informed decisions, ensuring efficiency and optimal results in their welding tasks.

In summary, understanding when and why to use the 7018 or 7018AC can significantly impact the success of your welding projects, guiding you toward making the best choices for each unique scenario.