Introduction

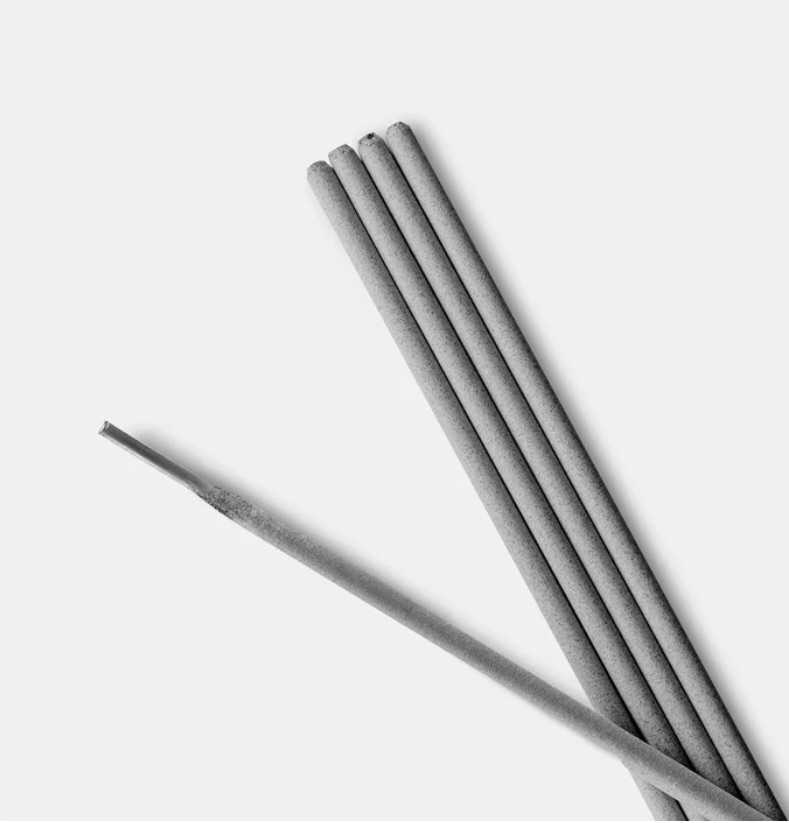

Nickel 55 electrodes are the go-to SMAW rods for repairing cast iron or joining cast iron to steel. Classified under AWS ENiFe-CI, these rods use a nickel-iron core designed to handle gray iron, ductile iron, and mixed-metal joints without cracking. The “55” refers to the approximate nickel content—about 55% nickel and 45% iron.

Shops that work on engines, pumps, gearboxes, or foundry castings use Nickel 55 because it offers a balance of strength, ductility, and machinability that other fillers can’t match. When standard steel electrodes are too brittle or nickel 99 is too soft, Nickel 55 hits the middle ground.

Types and Variants

Most Nickel 55 electrodes follow ENiFe-CI chemistry, but manufacturers offer performance differences:

Nickel 55 AC/DC

-

Works on AC or DCEP.

-

Useful for older machines and field repairs.

High-Machinability Nickel 55

-

Tweaked slag formulation for easier slag removal.

-

Good for parts requiring post-weld machining or precision finish work.

Low-Heat-Input Nickel 55

-

Reduces thermal cracking on brittle castings.

-

Better for thin, contaminated, or unknown-grade cast iron.

Regardless of brand, the ENiFe-CI designation keeps chemistry consistent enough for repair use.

Key Features and Specifications

Composition: ~55% nickel / ~45% iron

-

Higher tensile strength than pure nickel fillers (Nickel 99).

-

Better ductility and crack resistance than steel electrodes.

Diameters: 3/32″, 1/8″, 5/32″, 3/16″

-

Match diameter to casting thickness and available amperage.

Current: AC or DCEP

-

Compatible with most SMAW machines.

Positions: All-position rated

-

Suitable for field repairs and complex geometry.

Typical Tensile Strength: ~70,000 psi (AWS minimum)

-

Strong enough for structural repair, flexible enough to limit cracking.

AWS Specification: ENiFe-CI

-

Ensures consistent chemistry and predictable performance.

These specs translate directly to fewer cracks, cleaner machining, and better fusion on dirty or aged cast iron surfaces.

Usage and Compatibility

Nickel 55 is a stick-only electrode. It is not designed for MIG, TIG, or flux-core processes.

Machine Compatibility

-

AC or DCEP transformer welders

-

Inverter SMAW machines

-

Portable stick welders

-

Ideal for field service trucks and shop repair stations

Notes for Welders

-

Nickel 55 is more crack-resistant than steel rods, but most cast repairs still require controlled preheat and slow cooling.

-

Compared to Nickel 99, Nickel 55 produces stronger joints but is slightly less machinable—important for load-bearing parts.

Common Applications

Engine Blocks (Gray Cast Iron)

Handles thermal cycling and localized heat without cracking.

Pump Housings / Compressor Bodies

Good for joining cast housings to mild-steel frames or flanges.

Gearbox and Transmission Cases

Allows buildup before machining sealing surfaces.

Foundry and Plant Maintenance

Fills casting defects, chips, cold shuts, or porosity.

Agricultural and Heavy Equipment Repairs

Reliable for high-stress service in dirty or uncontrolled environments.

Nickel 55 works because it fuses well to cast iron and steel, resists cracking, and leaves a machinable weld deposit.

Tips and Best Practices

Setup

-

Preheat castings to 250–500°F when possible.

-

Use the manufacturer’s low-amp recommendations (typically 70–110A for 1/8″).

During Welding

-

Maintain a short arc length for stability.

-

Use stringer beads—avoid weaving to reduce heat buildup.

-

Peen each bead lightly to relieve stress.

After Welding

-

Cool the part slowly (insulation, welding blankets, or bury in dry sand).

-

Do not quench or expose the part to rapid cooling.

Common Mistakes to Avoid

-

Welding cold on large or critical repairs.

-

Overheating the casting by running long, hot passes.

-

Using thick layers. Nickel 55 performs best with controlled, thin deposits.

Conclusion

Nickel 55 electrodes are a proven solution for cast iron repair and cast-to-steel joints. They provide stronger welds than pure-nickel fillers while maintaining enough machinability for post-repair finishing. For shops that regularly repair engines, pump housings, transmission cases, or heavy equipment parts, Nickel 55 remains an essential filler metal.

Key takeaway:

Use Nickel 55 when you need a strong, ductile, crack-resistant weld on cast iron—especially for structural or load-bearing repairs that still require machining.

Where to Buy:

Washington Alloy 55% Nickel Stick Electrode 10LB Package (3/32" – 10 LB.)

$284.08

In Stock

View Product

Washington Alloy 55% Nickel Stick Electrode 10LB Package (1/8" – 10 LB.)

$304.05

In Stock

View Product

Washington Alloy 55% Nickel Stick Electrode 10LB Package (5/32" – 10 LB.)

$263.52

In Stock

View Product

Weldcote Metals 55 Nickel Stick Electrode – 1# Package (3/32" Diameter)

$55.01

In Stock

View Product

Weldcote Metals 55 Nickel Stick Electrode – 1# Package (5/32" Diameter)

$52.12

In Stock

View Product