A true color auto-darkening helmet improves puddle visibility, reduces eye strain, and protects against arc flash. Not all budget helmets react quickly or provide clear optics—here’s what to check.

Key Takeaways

- True color lens improves puddle visibility

- Large viewing area (~3.94″ x 3.66″)

- 4 arc sensors for reliable switching

- Variable shade 4/5-9/9-13

- Solar powered with battery backup

Where to Buy

- Advanced Eye Protection with Blue Light Blocking Technology: This welding helmet features cutting-edge Blue Light Blocking outer lens, shielding your eyes from harmful blue light during welding, protects your eyes by filtering out most of harmful high energy blue light rays while letting through the less harmful portion of the blue light spectrum. This ensures long-lasting eye comfort and safety, making it ideal for extended welding sessions

- Multi-Application: Wide shade range 3/5-9/9-13, covering most common welding processes, ideal for TIG, MIG, MMA (STICK), CUT & GRIND. Easily accommodates Magnifying Lenses for close-up work

- True Color & Clear View: This auto darkening welding helmet is equipped with a 3.93″X3.66″ Large View, enjoys a True Color view with upgraded 1/1/1/1 optical clarity, improves visibility and reduced eye strain

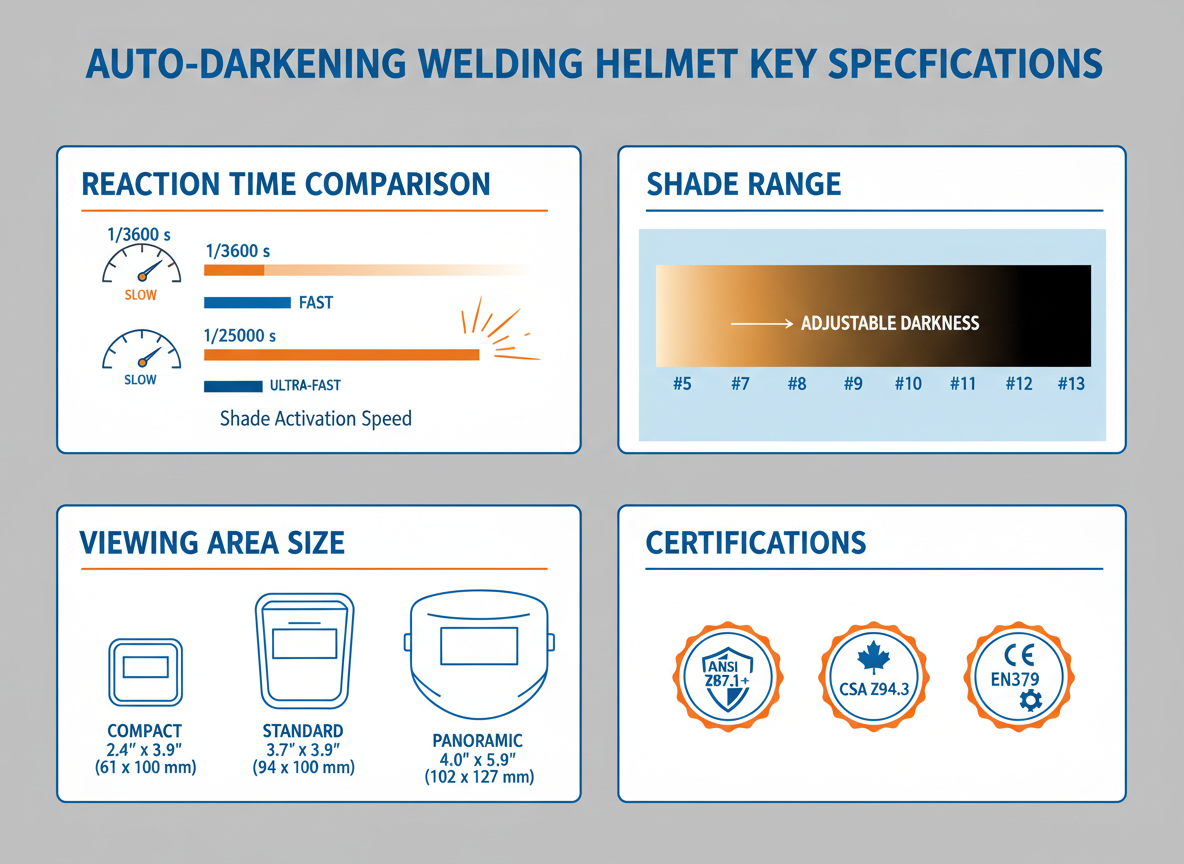

- Fast Auto-darkening: Features 4 Arc Sensors for reliable arc detection, ultra-fast switching (1/30000 sec), and adjustable Sensitivity and Delay Controls for perfect performance

- Long Service Life: Powered by solar panel technology and replaceable CR2450 lithium battery. Solar panel can transform harmful arcs into electrical energy not only for longer life, but also provides support for energy conservation and environmental protection

Last update on 2026-02-20 / Affiliate links / Images from Amazon Product Advertising API

Disclosure: As an Amazon Associate, Weld Support Parts earns from qualifying purchases.

Why True Color Matters

Traditional lenses tint green, masking puddle detail.

True color improves contrast and clarity, helping you:

- Track the weld pool

- Identify defects

- Reduce fatigue during long sessions

Performance & Compatibility

Suitable for:

- MIG

- TIG (increase sensitivity for low-amp TIG)

- Stick

- Plasma cutting

Always test before striking an arc.

Specs

| Spec | Value |

|---|---|

| Viewing Area | ~3.94″ x 3.66″ |

| Shade Range | 4 / 5-9 / 9-13 |

| Sensors | 4 arc |

| Power | Solar + battery |

| Weight | ~1–2 lbs (Verify) |

| Standard | ANSI Z87.1 (Verify) |

Who Should Buy

Best for:

- Multi-process welders

- Hobbyists upgrading from fixed shade

- Shop environments with varied amperage

Skip if:

- You require fixed shade only

- You weld exclusively outdoors in bright sunlight

Safety Notes

- Confirm ANSI Z87.1 compliance

- Inspect shell and headgear regularly

- Replace outer lenses when scratched

- Always wear flame-resistant PPE

FAQ

Is it good for TIG?

Yes—ensure proper sensitivity adjustment.

Does it run only on solar?

No, typically solar with battery backup.

Can lenses be replaced?

Most models allow easy lens swaps.

Is it rated for overhead welding?

Verify impact rating with manufacturer.