Grinding wheels live or die by speed, durability, and consistency. The Norton Gemini Fast Cut line is built for welders who need reliable metal removal without burning through discs or bogging down their grinder. If you’re prepping bevels, cleaning welds, or shaping stock on a daily basis, this pack of 25 offers production-friendly value with recognized Norton quality.

Key Takeaways

- 4-1/2″ × 1/4″ × 7/8″ Type 27 grinding wheel for right-angle grinders.

- Designed for fast stock removal on carbon steel and ferrous metals.

- Norton’s Gemini spec: balanced performance, long life, solid value for shop use.

- Reinforced for welding/fab environments—resists chipping and wheel fracture.

- Pack of 25 reduces downtime and per-disc cost.

Where to Buy

Amazon

- This Right Cut Angle Grinder is ideal for smoothing welds and for stock removal applications on a variety of steel materials, including 400 series stainless, hard carbon and soft carbon steels

- Sized as a 4 1/2 grinder wheel with a durable bond, this cutting wheel is designed to cut at high rates, ensuring it’s longer product life

- This grinder wheel design features an advanced ultra-thin type 27 depressed center that minimizes material loss during the grinding process

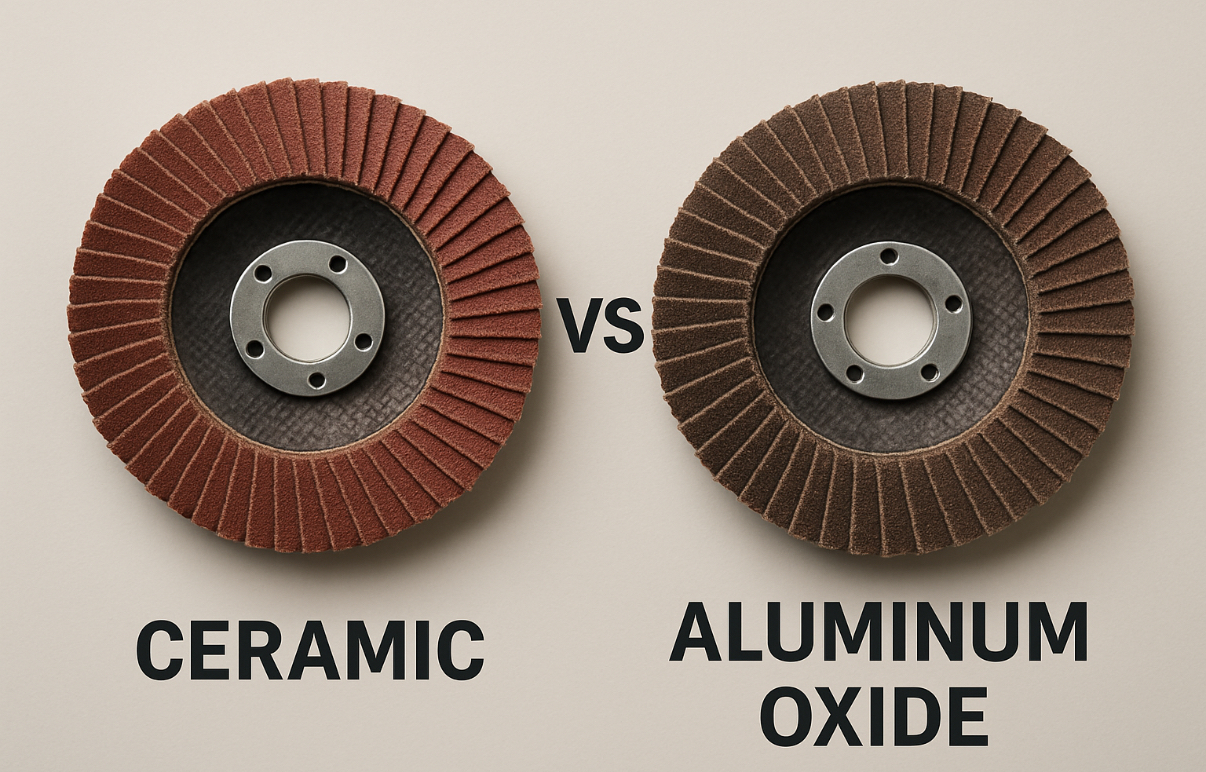

- This cutting disc is designed with an aluminum-oxide abrasive and a solid performance bond that delivers both a consistent cut rate and long wheel life on a right angle grinder up to 13580 RPM

- Wheel Type is 27 with a 4 1/2 inch diameter. Dimensions: 4-1/2 x 1/4 x 7/8 Inches. Comes as a pack of 25 cutting wheels

Last update on 2026-02-22 / Affiliate links / Images from Amazon Product Advertising API

Affiliate Disclosure: As an Amazon Associate, we earn from qualifying purchases.

Overview

The Norton Gemini Fast Cut wheel is aimed at welders, fabricators, and maintenance techs who need predictable cutting action and a strong wheel bond that holds up under heat and pressure. This 4-1/2″ wheel fits most common grinders used in steel fabrication, structural welding, railing shops, and job-site repair work.

Norton’s Gemini series is positioned above economy wheels but below their premium BlueFire and Norzon lines, making it an ideal daily-use wheel for general shop grinding.

Performance: What You Get in Real Use

Fast Stock Removal

The wheel uses an aluminum oxide grain blend optimized for rapid metal removal on:

- Mild steel

- Structural steel

- Carbon steel plate and shapes

- Weld bead cleanup

It cuts aggressively without glazing over, which helps maintain grinder speed and reduces operator fatigue.

Durability & Wheel Life

The reinforced fiberglass bond increases resistance to:

- Side-load pressure

- Gouging

- Impact during edge grinding

- Heat buildup

Shops using these wheels tend to see predictable wear patterns instead of premature chunking or cracking.

Control & Feel

- Smooth, stable tracking

- Less vibration than low-cost wheels

- Good control during bevel creation and weld cleanup

- Responsive cut without needing to force the grinder

This makes the wheel suitable for extended use during fit-up, prep, and post-weld finishing.

Best Uses

- Weld bevel prep

- Pass cleanup between welds

- Grinding down MIG or stick welds

- Plate edge shaping

- Structural fabrication

- Field welding repair

- Removing mill scale before tacking

These wheels are well-suited for small fab shops, steel contractors, and any workflow where workers need reliable, predictable performance during repetitive grinding tasks.

Safety Notes

- Follow ANSI B7.1 for grinding wheel use and inspection.

- Always mount wheels rated for RPM ≥ grinder speed (check your grinder’s nameplate).

- Perform a ring test before installation—discard wheels with cracks or defects.

- Wear ANSI Z87.1 eye protection, gloves, hearing protection, and FR clothing.

- Avoid grinding with excessive side pressure; use wheels designed for that purpose.

- Never grind near flammable vapors, dust, or gas sources.

FAQ

What grinders does this fit?

Any right-angle grinder using a 4-1/2″ wheel with a 7/8″ arbor.

Can it be used on stainless steel?

Not ideal. It can grind stainless, but aluminum oxide wheels may contaminate the surface. Use an INOX or stainless-rated wheel for best results.

Is this a Type 27 wheel?

Yes—depressed center (Type 27), suited for general-purpose grinding and weld cleanup.

Is this good for heavy weld removal?

Yes. The bond and grain blend are designed for aggressive stock removal.

Does Norton offer better-performing wheels?

Yes—the BlueFire and Norzon lines provide higher performance. Gemini is the balanced workhorse line.