Tungsten Inert Gas (TIG) welding remains one of the most precise and versatile welding methods available, favored for its ability to produce clean and high-quality welds. Among the many tungsten electrode options used in TIG welding, the 2% lanthanated tungsten stands out as a highly effective choice. Understanding the properties and applications of 2% lanthanated tungsten electrodes can help welders optimize their processes and achieve superior weld results.

What is 2% Lanthanated Tungsten?

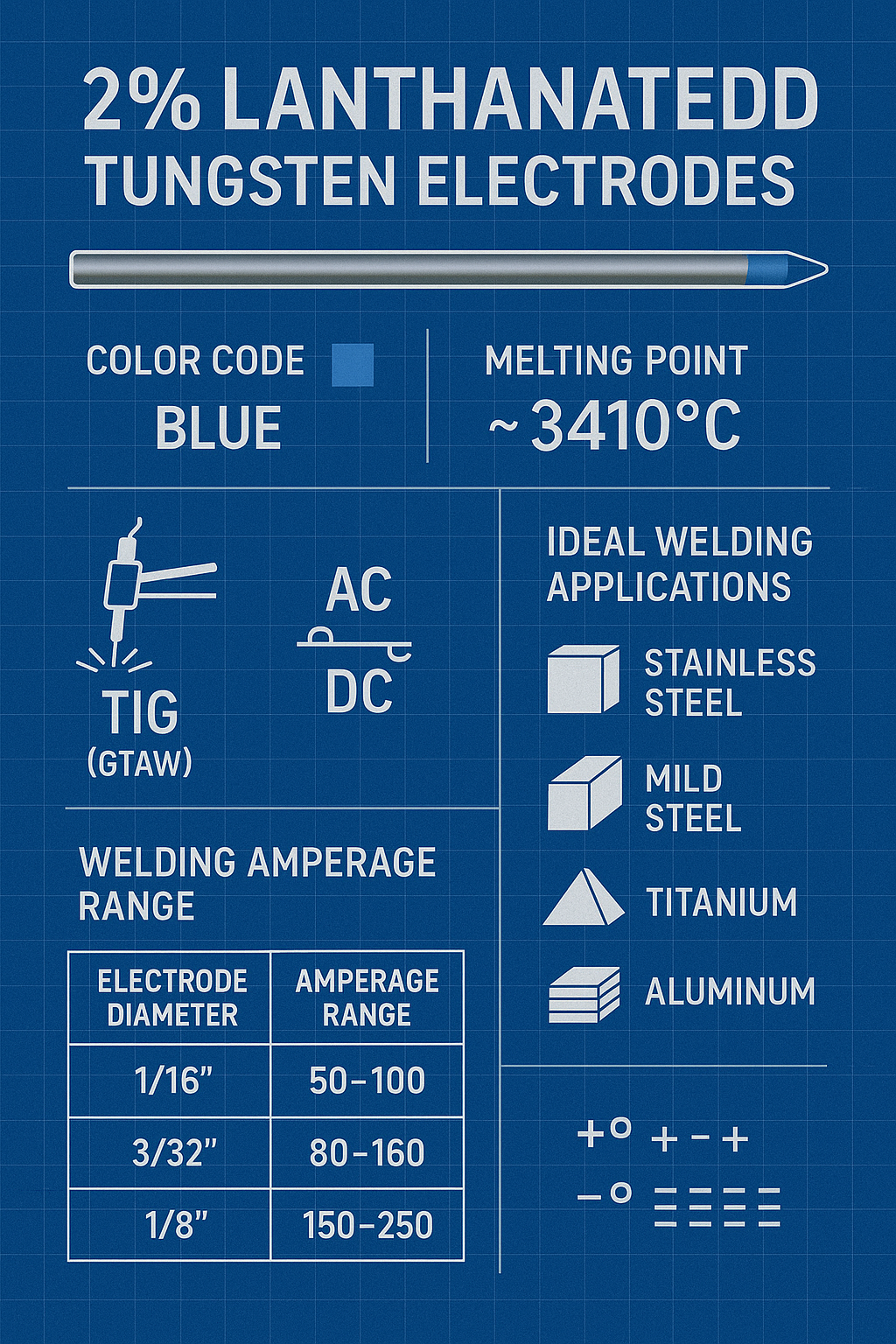

Electrodes in TIG welding are often alloyed with small amounts of rare earth elements to improve arc stability, longevity, and performance. The term “2% lanthanated tungsten” refers to tungsten electrodes that contain approximately 2% lanthanum oxide (La2O3) blended with pure tungsten. Lanthanum is a rare earth metal that significantly enhances the welding characteristics of tungsten electrodes.

Key Characteristics of 2% Lanthanated Tungsten

-

Arc Stability: One of the primary advantages of 2% lanthanated tungsten is its remarkably stable arc. This stability reduces spatter and helps maintain a consistent arc length, making it easier for welders to control the weld pool precisely.

-

Durability: These electrodes exhibit greater resistance to contamination and lower erosion rates compared to pure tungsten electrodes. This makes them longer-lasting and less prone to frequent grinding or reshaping during welding.

-

Versatility: Unlike some other tungsten alloys, 2% lanthanated tungsten works well with both AC (Alternating Current) and DC (Direct Current) welding. This versatility makes it suitable for a broad range of metals, including stainless steel, mild steel, aluminum, and magnesium.

-

Low Tungsten Spitting: The reduced tungsten spitting characteristic helps produce cleaner welds and prevents defects often caused by electrode erosion.

When to Use 2% Lanthanated Tungsten?

2% lanthanated tungsten electrodes are particularly preferred in welding applications where precision and appearance matter. They are widely used in aerospace, automotive, and high-end manufacturing industries. Here are some common scenarios where this electrode shines:

- Aluminum Welding: The balance of AC/DC capabilities allows for effective aluminum welds without the need to switch electrodes.

- Stainless Steel and Carbon Steel: Produces consistent and clean welds across various steel thicknesses.

- High Current Applications: The robust nature of lanthanated electrodes makes them suitable for higher amperage welding without degradation.

Tungsten Preparation and Usage Tips

To maximize the benefits of 2% lanthanated tungsten, proper preparation is essential:

- Sharpen the Electrode: Form a pointed tip by grinding longitudinally rather than across the tungsten to ensure a focused arc.

- Keep It Clean: Always clean electrodes before use to avoid contamination.

- Select Appropriate Size: Choose the correct diameter based on the amperage and thickness of the material being welded to maintain optimal arc characteristics.

Comparing 2% Lanthanated Tungsten to Other Tungsten Electrodes

While there are several tungsten alloy options—such as 1.5% thoriated, 2% ceriated, and pure tungsten—the 2% lanthanated typically offers the best balance between arc starting, stability, and electrode longevity. Unlike thoriated tungsten, lanthanated electrodes are not radioactive, which makes them safer to handle and dispose of. Compared to ceriated types, lanthanated electrodes usually have a longer life and better performance at higher currents.

Conclusion

2% lanthanated tungsten electrodes provide excellent arc stability, versatility, and durability, making them a valuable choice for many TIG welding applications. By incorporating this type of tungsten in their welding setups, professionals can achieve cleaner welds with greater efficiency and less frequent electrode maintenance. Whether tackling steel or aluminum projects, understanding the benefits and proper use of 2% lanthanated tungsten will help welders optimize their processes and deliver superior results.

Please note that we may earn commissions from orders placed using links provided to products.

- 2% Lanthanated (Blue) EWLa-2/WL20

- Principal Oxide: 1.8 – 2.2% Lanthanum Oxide

- Non-Radioactive. Best general purpose electrode for both Alternating Current (A/C) or Direct Current (D/C) using inverter or transformer based constant current power sources.

- Good for low-alloyed steels, non corroding steels, aluminum alloys, magnesium alloys, titanium alloys, nickel alloys, copper alloys.

- Good arc starts and stability, medium to high amperage range, low errosion rate.

Last update on 2026-02-20 / Affiliate links / Images from Amazon Product Advertising API

- 2% Lanthanated (Blue) EWLa-2/WL20

- Principal Oxide: 1.8 – 2.2% Lanthanum Oxide

- Non-Radioactive. Best general purpose electrode for both Alternating Current (A/C) or Direct Current (D/C) using inverter or transformer based constant current power sources.

- Good for low-alloyed steels, non corroding steels, aluminum alloys, magnesium alloys, titanium alloys, nickel alloys, copper alloys.

- Good arc starts and stability, medium to high amperage range, low errosion rate.

Last update on 2026-02-20 / Affiliate links / Images from Amazon Product Advertising API

- 2% Lanthanated (Blue) EWLa-2/WL20

- Principal Oxide: 1.8 – 2.2% Lanthanum Oxide

- Non-Radioactive. Best general purpose electrode for both Alternating Current (A/C) or Direct Current (D/C) using inverter or transformer based constant current power sources.

- Good for low-alloyed steels, non corroding steels, aluminum alloys, magnesium alloys, titanium alloys, nickel alloys, copper alloys.

- Good arc starts and stability, medium to high amperage range, low errosion rate.

Last update on 2026-02-20 / Affiliate links / Images from Amazon Product Advertising API

Leave a Reply