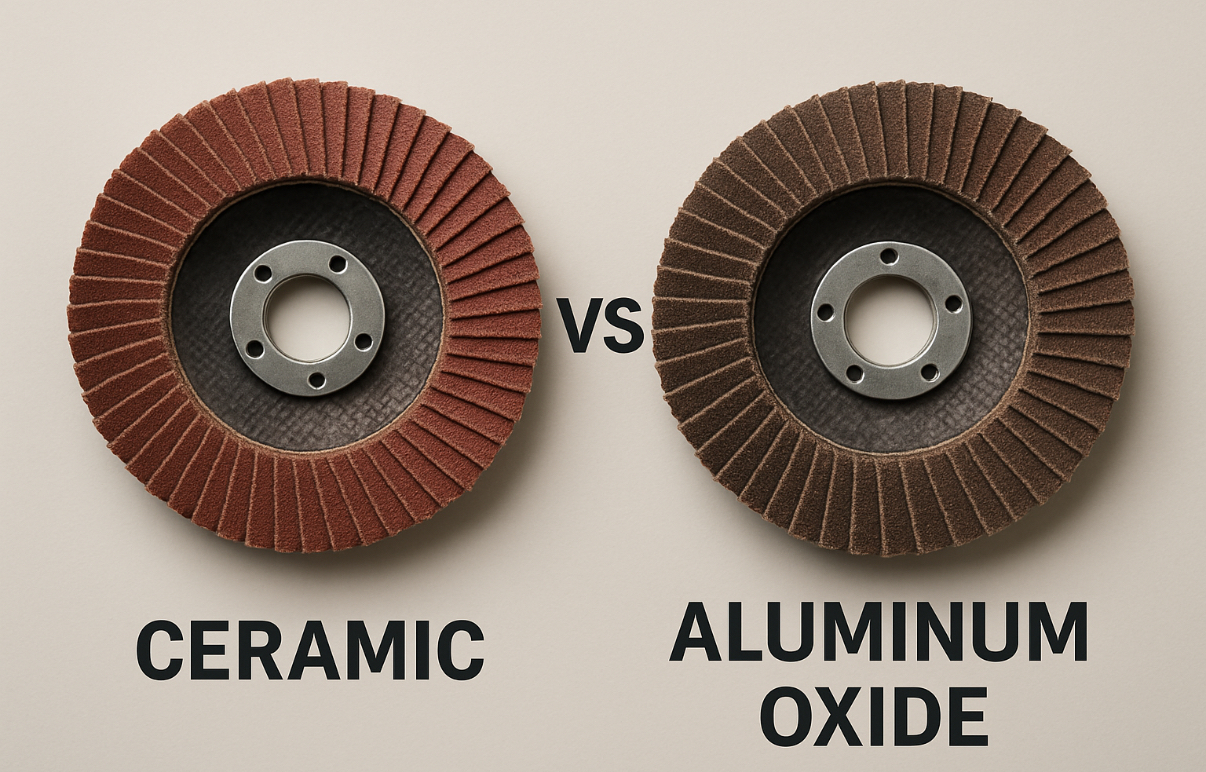

When it comes to abrasive flap discs, selecting the proper material can significantly influence the efficiency, lifespan, and quality of your grinding and finishing applications. Two of the most common abrasive flap disc materials you’ll encounter are alumina oxide and ceramic. In this post, we’ll compare these two options and help you decide which type will best suit your needs.

Alumina Oxide Flap Discs: Reliable and Cost-Effective

Advantages:

- Cost-Effective: Alumina oxide flap discs are generally more affordable, making them an excellent choice for general-purpose grinding, deburring, and finishing tasks.

- Versatile: Suitable for use on a variety of metals, including mild steel, aluminum, and other non-ferrous metals.

- Availability: Widely available across most hardware stores or industrial suppliers.

Drawbacks:

- Shorter Life Span: Alumina oxide discs tend to wear out quicker, especially when used on tough metals or demanding applications.

- Lower Heat Resistance: These discs generate more heat during grinding activities, potentially leading to discoloration or warping of sensitive metals.

| 4-1/2″ x 7/8″ 40 Grit | [See Price on Amazon] |

| 4-1/2″ x 7/8″ 60 Grit | [See Price on Amazon] |

| 4-1/2″ x 7/8″ 80 Grit | [See Price on Amazon] |

| 4-1/2″ x 7/8″ 120 Grit | [See Price on Amazon] |

Ceramic Flap Discs: Heavy-Duty Performance and Longer Life

Advantages:

- Longer Lasting: Ceramic abrasives are engineered to be highly durable, significantly outlasting alumina oxide discs in heavy-duty applications.

- Cooler Operation: Ceramic flap discs generate less heat during use, making them ideal for working with stainless steel, titanium, or other heat-sensitive alloys.

- Aggressive Grinding Action: Ceramic discs maintain a sharp edge longer, providing faster and more consistent material removal rates.

Drawbacks:

- Higher Initial Cost: Ceramic flap discs do come with a higher upfront price tag, although their longer lifespan and efficiency may offset the initial expense.

- Not Always Necessary: For lighter jobs or infrequent use, ceramic discs may be considered overkill and not cost-effective.

Making the Right Choice:

The decision between alumina oxide and ceramic flap discs largely depends on your specific application and priorities:

- Choose Alumina Oxide if: You’re performing general-purpose tasks, working on softer metals, or looking for a budget-friendly abrasive option for occasional use.

- Choose Ceramic if: You’re frequently grinding or finishing harder metals, require faster material removal, want to reduce downtime for disc changes, or need to minimize heat-related issues.

| 4-1/2″ x 7/8″ 40 Grit | [See Price on Amazon] |

| 4-1/2″ x 7/8″ 60 Grit | [See Price on Amazon] |

| 4-1/2″ x 7/8″ 80 Grit | [See Price on Amazon] |

Final Thoughts:

Both alumina oxide and ceramic flap discs have their place in your workshop. Alumina oxide discs offer versatility and affordability, making them suitable for general tasks, while ceramic flap discs provide superior performance, durability, and efficiency for more demanding applications. By carefully evaluating your needs, budget, and types of metal you’re working with, you can confidently select the best abrasive solution for your project.

** Note: ** I may earn a comission on any purchased made through Amazon from the links above.

Leave a Reply